Бесплатный фрагмент - The ABC of Qualimetry

The Toolkit for Measuring Immeasurable

About the authors

Professor Garry G. Azgaldov, a pioneer of Qualimetry, is a Doctor of Economics and a fellow of the International Academy of Informatisation, the Russian Academy of Natural Sciences, the Academy of Economic Sciences and Business, the Futures Research Academy, the Academy of Quality Problems and the International Guild of Quality Professionals. He is a chief researcher at the Central Economics and Mathematics Institute, Russian Academy of Sciences, Moscow.

Alexander V. Kostin is a PhD in Economics, a leading Russian expert in the valuation of intellectual property and intangible assets, a court-appointed expert, and a corresponding member of the Russian Academy of Quality Problems. He is a senior research fellow at the Central Economics and Mathematics Institute of the Russian Academy of Sciences (CEMI RAS, Moscow), the founder of the world’s first Online School of Intellectual Property Appraisers, and the author of the LABRATE ROYALTY PRO royalty-rate calculation method. He serves as the Chair of the International Committee on the Economics of Intellectual Property of the Eurasian Organization for Economic Cooperation (EOEC) and as the Academic Secretary of the Scientific Council on Intellectual Property Issues under the Department of Social Sciences of the Russian Academy of Sciences.

Professor Alvaro E. Padilla Omiste is a Doctor of Education, a Biochemist and a Bolivian Chemist. He is a Lecturer of Distance learning programs, Education Management and Education Research Methodology at several Bolivian and Latin American universities; Author and Co-author of several books and articles on issues related mainly to the R & D and innovation.

Introduction

Anything that people produce with in aperiod of time, as well as, anything they encounter in the course of commodity exchange and consumption and, generally in their everyday life, can be expressed by a set of four elements: products, services, information, and energy. Each of these elementscan be fully described by three fundamental variables:

— Quantity (in conventional units of measurement);

— Cost of production, distribution and consumption / utilisation / exploitation / application of a unit of quantity; and

— Quality of the unit of quantity.

The first of these, quantity, is basic to calculation in the engineering disciplines. The second, cost, is recognised and studied by the body of economic disciplines. As to the third characteristic, quality, until quite recently it was seldom if ever taken into account by either engineering or economic or management disciplines.

The reason was a lack of a theory and a toolbox for avalid quantification (assessment) of quality, such as the quality of products / services / information / energy. Without this kind of assessmentit is very difficult, if not impossible, to maintain an effective economic or social structure, e.g., an important omnibus structure called the quality of life, otherwise known as the standard of living.

The foregoing applies, among other things, to management, political, legislative or analytical activities.

For at least one time, almost every manager (as well as a policy-maker, law-maker or analyst) has faced the problem of quantitative evaluation of quality, e.g., the need for quality control; depending on the specifics of their work it may be the quality control of an industrial or a social process (including the control of life quality), a design, a product, personnel, etc.

In every such situation what the manager has to do is to convert the quality of a controlled object –a production or social process, a design, a product, personnel, etc. — within a given time from a given state, A, to a target state, B. Clearly, the manager cannot solve this problem unless he/she is capable of quantifying A and B, that is, assessing the object’s quality in quantitative terms.

Hereinafter in this ABC we will often discuss quality with special reference to the quality of life as the most important, succinct and general description of socio-economic processes. The quality of other objects, e.g., products, will be used to make our examples more graphic.

Secondly, quality must be quantified in those frequent situations where a manager must decide between two or more options. For example, with superior quality in mind a manager has to decide:

— Whether a consumer product is to be imported or to be manufactured at home;

— On an organisation/administrative structure best suited for controlling a social or manufacturing process; or

— An equipment package for building infrastructure facilities in an urban setting.

When the number of options is greater than two, given that the quality of each option is determined by a combination of parameters (more about it later), the inescapable conclusion is that if one is to address this class of problem one must be able to quantify quality.

Lastly, we need to quantify quality when dealing with economic and social problems where, if we are to improve calculation accuracy, we have to take into account qualitative as well as quantitative factors (that is to say, if the former cannot be expressed in currency units), such as social, environmental, ergonomic or aesthetic ones.

With these considerations in mind the reader is introduced to an ABC of qualimetry, a relatively new scientific discipline concerned with the methodology and total quantitative assessment of the quality of different objects and of some of their qualitative characteristics that do not lend themselves to measurement in common monetary units. The fact is that despite there being a sizeable body of writing (more than 100 books with the term qualimetry in their title) any information found there is usually outdated and often plain wrong, which may lead to wrong decision making processes.

Because of the limited size of this text we can only describe the basics of qualimetry in its most common version rather than cover this discipline in full. For this reason Chapter 1 will focus on the so-called short-cut method of qualimetry. Unlike other methods, the approximate and the exact ones, it takes far less time to learn, understand and apply; however, it will help you solve, with reasonable accuracy, quite a few problems encountered in practice.

This ABC will be useful to specialists in the executive, regulatory and legislative branches, as well as, to all those interested in the methodology of decision-making pertaining to the quality of different kinds of objects.

The authors would appreciate any constructive comments on the subject matter of this book.

Chapter 1. Qualimetry in Outline

Over the years following the appearance of qualimetry, many new scientific related with this science resulted, but most of them are scattered over various small editions and remain virtually inaccessible to the broad reading public interested in quality assessment issues. The purpose of this section then is to give a systematic and fairly complete picture of the state of the art in the theory and practice of evaluation of the quality of various objects of a social or economic character.

1.1. General Information about Quality and Quality Control

1.1.1. The Essence of Quality and Quality Control

The Concept of Quality and What Makes It Different from Other Similar Concepts

As already noted in the Introduction, Quality Control is one of the main applications for qualimetry.

Unfortunately, modern economic theory and economic practice alike, has unambiguous and common interpretations of the terms quality and control, leading to frequent misunderstandings with resulting in completely different approaches to many important issues. For example, “What really happens to an object (e.g., life quality), which, as often claimed, is being controlled?” Is the process indeed a control one? Is it indeed quality and not something else that is subject to control?”

These are not idle questions. Unless we figure them out we cannot count on success in addressing the issue of quality. Therefore, let us clarify our definitions of the key terms, quality and control. At the outset we introduce some terms based on which it will be possible to define the desired term, quality control.

Object, a thing or a process; as applied to the theme of these introduction:

— An animate thing (e.g., a city dweller) or an inanimate one (e.g., a motor car);

— A product of labour (e.g., a dwelling house) or a product of nature (e.g., a natural landscape around an urban settlement);

— A physical object (e.g., an industrial enterprises) or an ideal one (e.g., an artwork made out in a book title);

— A natural object (e.g., a landscape) or a man-made one (e.g., a set of landscape design structures);

— A product (e.g., a piece of clothing) or a service (e.g., a medical service);

— Items (e.g., motorways) or processes (e.g., life activities, which collectively form the quality of life).

In what follows the term object will apply to an object (which can be called “singular”) such that its quantity, in common measurement units, equals one. Then, a city can be an object but not three cities taken together; likewise one airplane, one specialist, etc.

Property. A feature, characteristic or peculiarity of an object, that becomes apparent during its consumption/operation/use/application (henceforth, all these terms are used interchangeably) according to the purpose of its use (e.g., the mean lifetime of a community).

The mention of the condition “according to its purpose” is caused by the following considerations: Imagine an emergency situation in which indoor sports facilities have to be used as temporary shelter for the inhabitants of a city whose homes were destroyed in a disaster (such as caused by Hurricane Katrina in New Orleans in 2005). The floor area of the interior, which can accommodate refugees, would seem to be a characteristic of a sports structure. The thing is that this kind of utilisation of athletic facilities is abnormal, out of keeping with their purpose. Therefore, a feature of a sport hall such as “the number of refugees it can accommodate” cannot be regarded as its “property” in a qualimetric sense.

We draw the reader’s attention to one more circumstance, which, although mentioned in the definition of the term property, is sometimes neglected in practice. Properties are not just any features/characteristics/peculiarities of an object, but only those that occur during its production or consumption/application/use/operation.

For illustration we give the following example (which for greater clarity relates to product quality). Any product made of a ferromagnetic material is known to possess the quality of magnetostriction, that is, the ability to change its shape and size in response to changes in the magnetic field.

Let us consider two different kinds of products made of a ferromagnetic material: a mechanical chronometer watch and the track shoes of a caterpillar tractor. Obviously, magnetostriction is incident to both.

In a chronometer magnetostriction shows in the way its accuracy is affected by exposure to a strong magnetic field. As for tracks, the phenomenon of magnetostriction in a physical sense does take place during their operation, but its impact (e.g., the magnitude of the absolute and relative changes in the linear and volumetric dimensions of the tracks) does not affect the performance of the tracks as part of a caterpillar belt. We can assume, therefore, that magnetostriction is not manifested in the consumption of these products (that is not in a physical but an economic sense.)

It follows that for an object like a chronometer watch, the presence of magnetostriction is to be considered one of its properties, whereas for a caterpillar track it is not a property in the sense outlined above in the definition of property.

Quality is a property representing a set of those and only those properties that characterise the consumption results of an object, both desirable and undesirable, excluding the cost of their creation and consumption. That is to say, this set includes only properties associated with the results achieved in consuming an object, and does not include ones associated with the cost of providing these results.

Notice that:

(1) The properties that constitute quality do not include those that manifest themselves in the course of production/creation/development/manufacture of objects (hereinafter, unless otherwise indicated we shall generally use instead of four terms — production, creation, development, manufacture – a single umbrella term, production);and

(2) The entire life cycle of an object will be conventionally considered to consist of only two broad stages, those of production and consumption, with the consumption stage including what is known as distribution (which is only applicable to some objects, e.g., products of labour but not the quality of life).

Thus, when we analyse the quality of an object we can — even must — ignore its manufacturing technique and its production and consumption costs and focus instead on the results, both positive and negative, achieved at its consumption stage.

Cost Effectiveness. The totality of properties characterising the capital input into the production and consumption of an object. (In some cases cumulative costs can be represented by so-called reduced costs or full costs.).

From the definitions and interpretations of the terms quality and cost-effectiveness it follows that the entire set of properties of an object can be divided into two disjoint subsets: the properties that form the quality of the object and those that form its cost effectiveness.

As consumers are not normally only care for either the quality of an object ignoring its cost effectiveness or, alternatively, its cost effectiveness without regard to its quality, the science of qualimetry, naturally, felt the need for a characteristic that would take into account the entire set of properties associated both with the consumption of an object (its quality) and the costs incurred (its cost effectiveness).

This characteristic is termed integral quality in qualimetry.

Integral quality. The property of an object describing the sum of its quality and cost effectiveness. Thus, integral quality is the most general characteristic of an object, which factors in all of its properties.

It should be noted that the engineering and economic literature uses concepts and terms similar in meaning to the ones introduced above, quality and integral quality. We will consider these concepts starting with those who are close to the concept of quality.

The term engineering level is usually applied to the quality of products (but not, e.g., to the quality of life). It is almost identical in scope to the term quality. However, it has several shortcomings compared to the latter:

(a) In a purely linguistic sense, with some objects this term is perceived as much less suitable than quality. Imagine pronouncing phrases like “the engineering level of ladies” perfume”, “the engineering level of milk,” “the engineering level of a specialist,” “the engineering level of a managerial decision,” or “the engineering level of life.” Substituting quality for engineering level immediately improves the sound of these identical terms: “the quality of ladies” perfume,” “the quality of milk,” “the quality of a specialist,”“the quality of a managerial decision,” “the quality of life.”

(b) The term quality has a long history dating back to Aristotle’s days, while the term engineering level came into being (mainly in the Russian literature) in the last 30 — 35 years. This brings up the natural question: why use a new term if we have a long-established synonymous term?

(c) It is common knowledge that the quality of a finished product is defined by three factors: the quality of its design, the quality of its raw materials and semi-finished products, and the quality of its manufacture (that is, the extent to which its design parameters are met in manufacture).Sometimes the term engineering level refers to what is termed design quality in qualimetry.

Then the question arises: why introduce a new term, engineering level, if we can do with the good old term, quality (or more precisely, design quality)?

For these reasons, in the science of qualimetry (and in this ABC) the term engineering level is not used.

The term technical excellence is an absolute synonym of engineering level. Therefore, all that was said above regarding engineering level applies to technical excellence.

The term utility describes a property that characterises the aggregate of quantity and quality of an object (see, e.g., [1]).

For example, the utility of two houses is greater than that of one of exactly the same quality. However, utility and quality means the same thing when applied to one unit of quantity of an object. That is to say, we can assume that quality is the utility of one unit of quantity of an object. Since the quantitative estimation toolbox is better designed for quality than for utility in what follows we will use mainly the term quality, that is to say, consider mainly objects whose number is equal to one unit.

The term value is synonymous with utility but its use is normally restricted to the philosophical literature. All that we have said above about utility holds for value.

Concept of use value. If as shown above, quality is the utility of an object unit (that is, a property inherent in the object),use value is the object possessing this property, i.e. utility. As applied to an object whose quantity equals unity, use value is the object possessing this property whose quantity equals unity (see [1]). As the subject matter of this ABC is the quality of an object (e.g., the quality of life) and not its quantity, hereafter the concept of use value will not be generally used and our exposition will be in relation to the concept of quality.

The term efficiency has many different interpretations. With regard to the most commonly used one it is very close to integral quality. However, because of its ambiguity we will use it instead the term integral quality. On the other hand, since most of the statements relating to the concept of quality remain in force and applicable to the concept of integral quality, the latter will be used hereafter only in specified cases.

We introduce some more concepts related to the concept of quality.

Property / quality / integral quality index. Is a quantitative characteristic of a property / quality / integral quality.

Index value. Is a specific numeric value that an index can take. For example, the values for the property index “room temperature” can be 20° С or 22° С. Here the numerals 20 or 22 are the values of the property index. Similarly the term index value can be illustrated (this time in dimensionless units) with reference to quality. Let the quality index be expressed by the symbol Кк. Then in the expression Кк = 0.68 the numeral 0.68 is the value of Кк.

Where quality is analysed in general terms (i.e., not in a numeric but in an alphabetic form) the value of the index is expressed not by a numeral but by a lowercase letter (as opposed to the index itself, which is always denoted by a capital letter). For example, the expression KК= k1K reads as follows: the quality index KK has the value k1K. This applies to a quality index but also to a property index, an integral property index, etc.; to any index at all.

After we have clarified the meanings of the basic concepts related to the term quality we can analyse concepts related to the term control, which is in practice often linked with quality (e.g., in phrases like “product quality control”).

1.1.2. The Term Control and Its Difference from Other Similar Terms

Let us denote a given time point byt1and a time point in the future by t2 (obviously, t2>t1). Let us denote by ΔT the time elapsed from t1 to t2: ΔT= t2 — t1.

Let us define our terms:

Pre-settime ΔTSET: a time period ΔT, the value of which is pre-set by a human controller.

Indefinite period of time ΔTi: a time period ΔTi the value of which is not pre-set/defined by human controller.

Let us introduce some terms:

Object state: the state of an object at an instant defined by its quality whose index has the value kK.

Given object state: the state of an object at a given (initial) instantt1at which the value of its quality index is k1K.

Future object state: the state of an object at a future instant t2at which its quality index will be k2K.

Quality variation: a value given by the expression ΔKK = k2K- k1K.

Pre-set quality variation ΔKKPRE: a quality variationΔKK the value of which is given in advance by a human controller.

Indefinite quality variation ΔKK?: a quality variation ΔKK the value of which is not given by a human controller.

Object quality control: the transfer of an object from a given state k1K to a future state k2K at ΔKKPRE with in ΔTPRE (To rephrase it, to control the quality of an object is to ensure in the object a pre-set quality variation ΔKKPRE with in a pre-set time ΔTPRE).

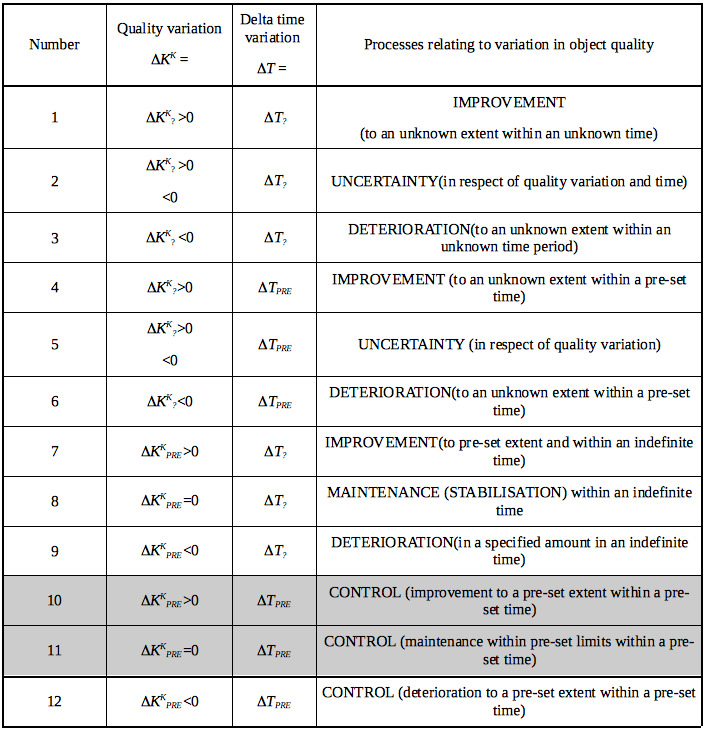

It follows from this definition that if any of these conditions were not met (e.g., indefinite timeΔT? instead of pre-set time ΔTPRE or in definite quality variation ΔKK? instead of pre-set quality variation ΔKKPRE is used) it would be improper to refer to it as quality control. In actual fact a different process is in progress. Table 1 shows different processes and their relation to the quality control process.

Table 1 lists twelve situations differing in their combinations of ΔKK (quality variation) and ΔT (time variation). Each has an associated process type related to quality variation, from total uncertainty to quality control, which may vary within pre-set limits within a pre-set time.

Regrettably, in practice the term quality control is frequently applied to processes that can at best be described as quality improvement (see, e.g., line 4 above).In these processes (which in most cases concern industrial products) the value of an object’s property index could be improved by so many per cent within a pre-set time; e.g., the life of a component part could be increased by 30%.It is then concluded that the quality of the object improved by the selfsame 30% supposedly as a result of quality control.

There are two principal fallacies here. One is that the magnitude of increase in the value of the quality index was determined incorrectly, taking no account of the fact that an improvement in the value of a property of an object by α% almost always leads to an improvement in its quality index by β% (with α<β).

The second fallacy is neglect the following: a quality improvement in one property of an object will result in an improved quality index of the object to the extent that none of its other property indices has deteriorated. Yet, this is a fairly common occurrence. Let us suppose that in the above case a 30% increase in the life of a component part is often accompanied by an increase in its mass. This leads to a deterioration of its “product mass” property by so many percent. Unless we make a qualimetric calculation we cannot say a priori whether — and by how many per cent — the quality of the product deteriorated or improved. (Proofs of both these assertions are to be found in books on theoretical qualimetry; see, e.g., [2]).

Therefore, it often happens in practice that the term quality control is applied to processes which, in control theoretic terms, cannot be considered quality control and, not infrequently, cannot be even called quality improvement because in reality they only ensure some indefinite quality variation (see lines 2 and 5 in Table 1 above).

The grey background in Table 1 is used to highlight two lines, 10 and 11, which represent the criteria to be met if we are to have a real quality control process. Line 10 describes the conditions under which, as common sense tells us, quality control is really achievable. That is to say, it is about a quality improvement is achievable to a pre-set extent within a pre-set time.

The case introduced by line 11 also belongs to control processes, though it is less apparent in the usual sense. Its only difference from case 10 is that the latter achieves a quality improvement (accordingly, ΔKK > 0), whereas in case11 no improvement is envisioned, the only intention being to keep quality from deteriorating within a pre-set time period, i.e., to set it at a constant level, ΔKK = 0).

The process described in line 12 is also related to quality control is totally unobvious to common sense. In pure theory, however, one can imagine a situation where the goal is not to increase but to decrease the quality of a product within pre-set limits and within a pre-set time, e.g., in order to cut production costs so as to boost demand. Since this is more academic than a real-life situation the respective line (12) in Table 1 was not highlighted with grey.

The foregoing interpretation of quality and quality control suggests that if we are to control quality we must be able to calculate the values of ΔKK. To do it we must, in turn, be able to quantify or estimate quality using its index KK. Consequently, we need a tool for the quantification of quality, which is provided by qualimetry.

There were also other factors, which made the appearance of qualimetry necessary, even inevitable. They will be discussed in the section that follows.

1.1.3. The Origin, Growth and Future of Qualimetry

1.1.3.1. The Reasons Behind the Rise of Qualimetry as a Science

Qualimetry is a consequence of knowledge quantification

The term qualimetry (from the Latin quale, “of what kind”, and the Greek μετρεω, “to measure”) was initially applied to a scientific discipline studying the methodology and problems of quantitative assessment of the quality of various objects, mainly of industrial products [3]. By 1970 enough experience had accumulated to permit a thorough investigation of qualimetry, its subject matter and its relations with various scientific fields. At the same time there was a growing awareness of the need to expand the scope of qualimetry from product quality (which was the focus of some researchers) to the quality of objects of whatever nature, including socio-economic objects such as the quality of life.

When the term (and the respective concept) was first used it seemed unexpected, almost fortuitous; some still regard it so.

However, it would be wrong to speak of the fortuity of qualimetry. On the contrary, its appearance should be seen as one of the many perfectly natural signs of the general broadening of the scope of quantification and the use of quantitative methods in scientific and, generally, cognitive activities at large.

The universal and imperative nature of this tendency to expand the use of quantification as a major tool of cognition was succinctly stated by Galileo, who said “Measure what is measurable, and make measurable what is not so.” The Russian Mathematician D. B. Yudin expressed nowadays essentially the same idea: “Quality is a yet unknown quantity”.

Many great minds were aware of the important influence that mathematics, as a general framework of quantification techniques, has exerted on the development of science.

K. Marx was of the opinion that a subject could be called a science if it had a mathematical foundation. A century before him, I. Kant wrote in his Metaphysical Foundations of Natural Science, “I maintain, however, that in every special doctrine of nature only so much science proper can be found as there is mathematics in it”. Three centuries before Kant, Leonardo made a similar statement: “No human investigation can be called real science if it cannot be demonstrated mathematically”. Five centuries before Leonardo, in the 9th century, the famous Arab scientist Abu Yusuf Ya’qub ibn Ishaq al-Kindi, who saw in mathematics the basis and prerequisite of all science, including philosophy and natural history, pursued a similar line of thought. Another thirteen centuries earlier the Greek philosopher Xenocrates of Chalcedon expressed the ancients” idea of mathematics in the following maxim: “Mathematics is the handle of philosophy”. Dozens of years before Xenocrates, or 2300 years before our time, his teacher Plato said, “Exclude from any science mathematics, measure and weight, and it is left with very little”.

Quantification is steadily broadening its scope of application, as evidenced by the growth of scientific disciplines or technical problem solving techniques that include the Greek μετρεω in their name. Here are a few examples:

Absorptiometry; autometry; autorefractometry; adaptometry; axiometry; actinometry; algometry; amperometry; angiostereometry; anthropometry; astrocalorimetry; astrometry; astrophotometry; audiometry; acidimetry; batimetry; biometry; bibliometry; veloergometry; visometry; viscosimetry; gigrometry; hygrometry; hydrometry; glucometry; gravimetry; gradiometry; densitometry; didactometry; dilatometry; dynamometry; dielectrometry; dosimetry; dopleometry; isometrym impedancemetry; inclinometry; interferometry; cliometrics; calipometry; calorimetry; chelatometry; conductometry; craniometry; coulometry; lipometry; luxmetry; mediometry; mercurimetry; morphometry; scientometrics; nitritometry; optometry; ordometry; oscillometry; optometry; perimetry; pirometry; pH-metry; planimetry; polarimetry; psychometrics; potentiometry; pulseoxymetry; radiometry; radiothermometry; redoxmetry; roentgenometry; refractometry; sensitometry; sociometry; spectrometry; spectroradiometry; spectropolariometry; spectrophotometry; spirometry; spiroergometry; stabilometry; stereometry; sphincterometry; tacheometry; tensometry; technometry; tonometry; turbidemetry; uroflowmetry; fluorimetry; photogrammetry; photocolorimetry; photometry; chronometry; equilibriometry; econometrics; exponometry; electrometry; echobiometry. Qualimetry is also a member of this steadily expanding family. (It would be wrong, however, to believe that every discipline using quantification has metry / metrics in its name.)

Qualimetry: A Tool for Enhancing the Efficiency of Any Kind of Work

What happened for the qualimetry to appear in the 1960s?

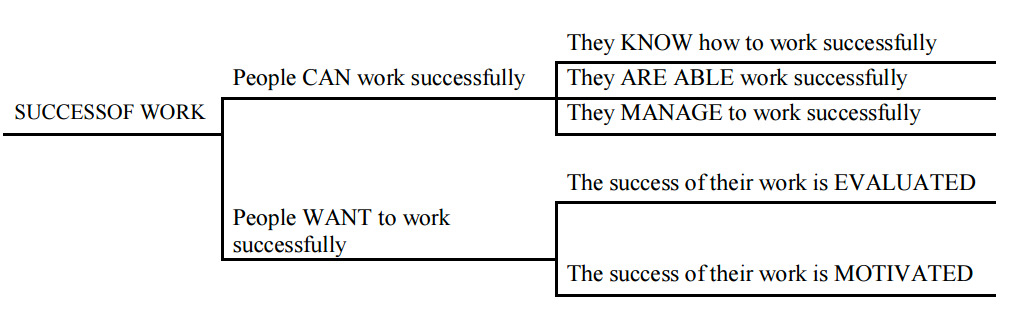

Modern management science has formulated five necessary and sufficient conditions for the success of any work, which can be represented by a “condition tree” (Figure 1).

Four of these conditions, TO KNOW, TO BE ABLE, TO MANAGE, and TO MOTIVATE, are relatively easy to meet technically; regulatory documents for respective calculations are already in place. For example, every productive industry uses its own rate setter’s handbook (or a similar document), which is used to calculate the workforce and the time and tools needed to perform a piece of work (TO MANAGE condition). Other documents, like wage rate books, specify the requirements to be met in selecting the workforce to do some work successfully (TO BE ABLE condition).It is relatively easy to secure the TO KNOW condition: you only need to set the work executors a task. Finally, to meet the TO MOTIVATE condition all businesspersons or managers have a broad range of stimulatory actions they can use on their subordinates: material or moral; positive (“carrot”) or negative (“stick”); individualized or team-directed; one-off or time-phased, etc.

The TO EVALUATE condition is a very different case. What we evaluate is work. Any work (and its output) is characterized by three parameters: quantity, cost and quality. Arguably, the numerical evaluation of the quantity and cost parameters does not present any essential difficulties to most occupations in the real sector.

We have a different situation with the quality parameter. Here two aspects must be taken into account: the quality of individual labour and the quality of teamwork. As for individual labour, evaluating is just a trivial task (particularly if it is to be done in a quantitative form and with due regard for the many characteristics that constitute its quality).

Evaluating even the simple labour of an industrial worker poses difficulties: it is by no means always that it can be evaluated using a simple reject rate index. These difficulties multiply when it is a matter of quantitative assessment of the quality of complex labour, e.g., brainwork.

Here is an example to illustrate the importance and complexity of this task. Back in the early 1970s a group of UNESCO experts surveyed 1200 research teams in Austria, Belgium, Finland, Hungary and Sweden. Their conclusion: the most vexed problem in raising working efficiency in science is the lack of a reliable methodology for assessing the quality of work of individual researchers and research teams. (Similar examples can be cited with respect of managers, health professionals, engineers, teachers, administrators, and some others.).

Let us now look at the issue of assessment of the quality of teamwork. It stands to reason that the quality of output is its most important characteristic. As already mentioned, the outcome of any teamwork is, a product, a service, some information or energy. Of these four the product is by far the most complex in terms of the quality assessment method and the most important in terms of the breadth of its existence domain, given that more than twenty million kinds of products are manufactured by developed economies over the world.

It all goes to show that:

1. In the present-day context, successful, i.e. effective, productive work is a key condition of the economic health of both an individual company and a country at large.

2. When we address the problem of increasing the success/efficiency of any labour the key element is the quantitative assessment– both of the process and the outcome of labour; primarily its product.

3. Of the three characteristics of labour (and its outcome) — quantity, quality and cost — quality is the most complex one in terms of quantitative assessment.

4. Until quite recently, the approach to the problem of quantitative assessment of quality (primarily of products) lacked sound methodological support. At best, isolated quality quantification techniques were created, which had not any sound and unified rationale to support them. As a result, different quantifications of the quality of the same object could be worlds apart if calculated by different methods.

5. A natural corollary to propositions 1—4: in the early post-WWII years every industrialised country felt the need for scientific rationalisation of methods of quantitative assessment of the quality of production work and its outcomes.

6. It was F. Engels who noted that when a technical need appears in society, it pushes science forward faster than a dozen universities. The origins of qualimetry can be seen as a natural response to a pressing need for generalisation and perfection of the techniques of quantitative assessment of quality.

1.1.3.2. History of Qualimetry: From Aristotle to Our Times

Theoretical Reason for the Relatively Late Origin of Qualimetry

One may ask: why did qualimetry appear as an independent scientific discipline in the 1960s and not before?

There were two principal reasons.

The first, which we will tentatively call “theoretical”, is as follows. The term quality has existed in science for as much as 2500 years, since the days of Aristotle. His usage of the term referred to different concepts. (For convenience, hereafter the respective definitions for these concepts will be given a modern interpretation, in a concise form, which are more familiar and comprehensible than Aristotle’s definitions. — Auth.). Subsequently, it was depending on its interpretation that it was decided whether or not it was necessary and possible to quantify/estimate this concept.

Interpretation I: Quality is an essential certainty of an object (i.e., a thing, phenomenon or process), which makes it what it is and not something else. In other words, quality is the kind of certainty that distinguishes, say, a human from a horse or a table.

This interpretation was dominant for centuries and it was not until the 20th century that it gradually started to fall into disuse; today, it is of interest almost exclusively to professional philosophers. Clearly, in most cases it makes little sense to refer to this interpretation of quality quantification or estimation; possible exceptions may be biological taxonomy or computer-based pattern recognition.

Interpretation II: Quality is an essential feature or property characterising a given object. Or, as Aristotle said, “… for example, warmth and coldness, whiteness and blackness, weight and lightness, and likewise other similar definitions…”

Quality in this sense has long since been successfully quantified using tools of general sciences like metrology or commodity research of special sciences such as gravimetry, dosimetry, calorimetry, etc.

Because the contemporary literature of science and engineering is trying to get rid of polysemantic terms the second interpretation has all but grown out of use. The term property has come to replace quality, which fact was embodied in the U. S. S. R. State Standard (GOST) for product quality terminology back in the 1970s. Therefore, the above interpretation of the term quality has no direct relevance to our present discussion of quality quantification.

Interpretation III: Quality is the totality of properties of an object that become apparent during its intended use (operation, application or consumption).In other words, quality is a characteristic of an object such that if it is quantified it would allow, with the simultaneous recognition of all the properties of the object in quantitative terms, to measure the goodness of the object when used (operated, applied or consumed).

This interpretation echoes another interpretation of Aristotle’s, who believed that the term quality could be, applied “… in relation to a good and a bad course of action and, generally, both good and bad belong here.”

This, third, interpretation has become the prevailing, almost exclusive one. That is due primarily to the scientific and technological progress in industry, when an enormous variety of similar products appear around the world every year, as well as to the rapid growth of international trade in products, services and energy.

Naturally, after this interpretation became well established and then almost exclusive the need was felt for numerous quality measurement techniques, and as a consequence, for a special discipline to give a scientific justification to such techniques. Before the twentieth century the third interpretation had found very little use; accordingly, there had been little use for quality assessment; hence, no need for qualimetry.

Above we considered the “theoretical” reason for the relatively late origin of qualimetry as a general method for quality quantification. (Late, that is, in comparison with the origins of the methods of measurement of the two other characteristics of any production output; quantity and cost.)

Practical Reason for the Relatively Late Origin of Qualimetry

There is a second reason, which we tentatively call “practical”. Its nature can be educed after we answer the question: Why qualimetry as an independent science was born as late as the mid-20th century if early quality quantification methods had appeared in and outside Russia already in the early twentieth century? We shall try to answer this question by drawing upon materials from the history of domestic science and engineering.

In Russia, the well-known mechanic and shipbuilder A. N. Krylov developed the first scientifically grounded quality measurement method back in the 1910s. He used it to solve the problem of choosing the best warship design from the many submitted to an international competition. (The best here refers to the totality of main properties, or quality, e.g. speed, protection, gun power, etc.). That selection was necessary for the restoration of the Russian navy after the heavy losses it sustained during the Russo-Japanese war.

Unfortunately, the Krylov method — which retains its importance among the many other qualimetric techniques to this day — upon development and successful application fell into oblivion, perhaps because it was designed for appraising the quality of rather unique objects, warships; a description of it could be found in a relatively obscure, almost rare publication (see [4]).

Some 20 years after Krylov’s method other methods for assessing the quality of different types of products appeared. They used a very different approach: where as warships were evaluated by the so-called “analytical” (i.e. non-expert) method, here a kind of expert approach was used. These methods began to evolve from the late 1920s, when the Special Council on Product Quality under the Presidium of the Supreme Economic Council of the U. S. S. R. found it necessary to use quality indices as an important tool in promoting technological progress and improving product quality. The reference was not to indexes of particular properties but to general (complex) parameters characterising product quality in general.

An essentially similar approach was used to assess the quality of some processes, for example, the performance of a printing shop. At the same time, so-called “comparative quality factors”, which had a regulatory character, were developed for some consumer products.

In the 1930s, the scope of application of expert methods for quality estimation expanded and they were incorporated in some industries and national standards as well as in departmental guidelines. For example, the first half of the 1930s saw the development and application of methods for evaluating the quality of some foodstuffs such as butter, canned fish, bread, confectionery and dried vegetables.

Similar techniques were developed not only for food products but also for consumer goods, such as cotton yarn, fabrics and textile goods, and for evaluating the quality of industrial products, e.g. tractors and farm machinery.

Quality measurement methods multiplied after WWII, in the 1950s. However, qualimetry did not emerge as an independent scientific discipline yet. Apparently, a general pattern relating to the conditions leading to the appearance of a new research topic was at work. Indeed, history shows us that before a knowledge field receives the status of a science there is a latent period when some of its principles and methods are generated and put to test. It is followed by the accumulation of a large body of unsystematised empirical data. At the same time the need may be felt for conceptualisation of the previous experience of generating those data and addressing emerging problems. The preconditions for a theoretical foundation of a new science are thus created. So emerged geometry in the ancient world. So emerged cybernetics, bionics, semiotics, operations research, econometrics, ergonomics, ecology, etc., in today’s world. So, again, it was in 1968 that qualimetry began to grow into a fully-fledged scientific discipline [3].

More recently qualimetry split into two separate branches or independent disciplines– applied qualimetry and theoretical qualimetry, which are briefly described below.

Theoretical Qualimetry

Qualimetry has evolved one more branch, theoretical qualimetry, which explores general methodological issues and problems of quantitative estimation of the quality of an abstract mathematical object rather than that of any particular objects (things, phenomena or processes). The rise of theoretical qualimetry served as a decisive argument in favour of making qualimetry into an independent scientific area. The fact is that an overwhelming majority of the quality evaluation methods that were proposed in and outside Russia before 1968 lacked of any comprehensive scientific justification and constituted, in effect, a mass of empirical data wanting analysis, justification and generalisation. (The only exceptions were the Krylov method and a 1928 paper by the Russian philosopher and theologian P. A. Florensky, dedicated to one of the problems of quantitative estimation of quality [5]).

An almost similar situation in the field of quantitative estimation of quality evolved elsewhere.

Then came a time when someone had to recognise the need for analysing, rationalising and generalizing the wealth of accumulated empirical material within a separate scientific discipline. Recognition could come somewhat earlier or somewhat later but it was bound to happen at around that time, in the 1960s or “70s.

Applied Qualimetry

This discipline seeks to develop applied techniques for evaluating the quality of new, here therefore unevaluated types of objects (things, phenomena and processes). The essence of this type of qualimetric research is described by the term applied qualimetry, which is one of the two branches of qualimetry as an independent scientific discipline. In this respect there appeared different sub disciplines, such as geographical qualimetry, automatic-machine qualimetry, construction engineering qualimetry, educational qualimetry, geodesic qualimetry, fabric qualimetry, etc.

Qualimetry Institutionalised

It happened that the first to arrive at this idea was a group of Soviet scientists (economists, civil engineers, car makers, architects), who were dealing with the problem of quantitative evaluation of quality. Gathering at an informal workshop in Moscow in November 1967, they came to the following conclusions:

1. The group members (Azgaldov, Glichev, Krapivensky, Kurachenko, Panov, Fedorov and Shpektorov) as well as some other researchers working on similar tasks were doing the same thing in terms of methodology, namely, trying to quantify quality, albeit in relation to quite different objects.

2. In their pursuits they faced almost identical scientific problem, and they used tools based on some common and similar concepts.

3. To achieve success in solving these problems and to improve the tools used it was advisable to bring together researchers engaged in quality evaluation in both the U. S. S. R. and abroad.

4. Such a pooling of efforts could best be achieved in the framework of a joint research activity that met all the conditions qualifying it as an independent scientific discipline.

5. The most suitable name for that discipline was qualimetry. Indeed, the Greek root metreo has become commonly accepted in the international lexicon of science. As for the Latin root qualis, its derivative words in the majority of the languages accounting for the bulk of scientific and technical literature means “quality” (cualidad in Spanish, qualità in Italian, kwaliteit in Dutch, Qualität in German).

Therefore, the term qualimetry is quite handy: it is concise and it accurately renders the scope of the “quality measurement” concept; its main components are intelligible to people speaking different languages; its structure makes it easy to form any derivative words like qualimetrologist (a qualimetry scientist), qualimetric approach (quality measurement approach) etc.

Furthermore, this term is part of a logically consistent system of concepts and terms; e.g., the science of quality (qualilogy) and the related science of quality measurement (qualimetry);one can draw an analogy with some other sciences: economics — econometrics, biology — biometry, psychology — psychometrics.

A paper by the workshop participants, which substantiated the above five propositions, was published in the journal Standarty i kachestvo [3]. It provided content for an international discussion in the journal during 1968, in which an overwhelming majority of the contributors supported the idea of a new scientific discipline. Thus qualimetry was born.

1.1.3.3. Qualimetry in Russia Today

What we briefly considered above is the past history of qualimetry. What about its present?

Formally, if our analysis of the progress of qualimetry over a period of 43 years since its inception should rely on absolute numbers alone it may show a fairly optimistic picture. However, it would be more appropriate to evaluate qualimetry by the same qualimetric approach, i.e., to consider not only absolute but also relative figures versus some benchmark or performance potential. We will apply this approach and try to show both the progress in and failures associated with the development of qualimetry. (Naturally, this analysis will take into account qualimetry-related facts and figures from the Soviet era as well as from the period of independent development of the Russian Federation).

As regards the scientific aspect, it may be noted that in the 1980s an Applied Qualimetry Laboratory operated at the National Research Institute for Standardisation and an educational qualimetry laboratory at the Academy of Pedagogical Sciences. These facts are gratifying by themselves. The word qualimetry was after a while removed from its title, and the laboratory changed its subject altogether. Something similar happened to the educational qualimetry laboratory.

Regarding another source of new scientific data in qualimetry, dissertation-oriented research, five doctoral and more than 45 master’s theses on qualimetric subjects have been defended to date. Not bad for a fledgling discipline. Unfortunately, the vast majority of this research deals with applied rather than theoretical qualimetry; in other words, qualimetry research is mostly growing, so to speak, in breadth not in depth.

In the Soviet era, two national scientific conferences dealt with qualimetry topics, one held in Tallinn (1972), the other in Saratov (1988); also, standing inter-republican scientific workshops were conducted in Moscow and Leningrad in the late 1980s. Due to a tight economic situation in which Russian science found itself in the 1990sthese workshops ceased functioning. (nor is there any news call) Perhaps the only positive development in this regard is an annual workshop (held since 1991) open to CIS participants, which deals with educational and health care applications of qualimetry.

It should be noted that qualimetry issues are discussed at special sections (or panels) of international conferences held by the European Organisation for Quality Control and the Asian Institute of Quality Management (Moscow — 1971., Oslo — 1974, Varna -1977; Yerevan — 1982, Madrid — 1983, Moscow — 1988, Delhi — 1989).

In addition, reports on the application of qualimetry to scientific and practical problems in other areas have been presented at more than national-scale 90 conferences, symposia and seminars held in Voronezh, Zvenigorod, Yerevan, Kiev, Kishinev, Krasnodar, Lviv, Leningrad, Moscow, Novosibirsk, Odessa, Pushchino, Riga, Saratov, Suzdal, Tambov, Tartu, Tashkent, Tbilisi, Uzhgorod, Ivano-Frankovsk and Kharkiv.

Qualimetry as an independent scientific discipline is taught in dozens of technical universities in Russia (the name of the academic subject is “Quality Control”).

Yet, given the multisectorial and interdisciplinary nature of qualimetry, these kinds of academic convention should be much more frequent, for experience shows that out of every 10 researchers (from junior research fellowsto members of the Russian Academy of Sciences) hardly one has ever heard anything about qualimetry and its potential.

Administrative staff shows no greater familiarity with the essence and potential of qualimetry. Indicative in this respect is the practice of top government statistical agencies, both in the Soviet Union and afterwards in Russia. In their published annual, semi-annual and quarterly statistical reports almost every one of the 800—1200 figures contained therein refer to either quantitative or purely economic (cost) performance indexes of the national economy. As for quality, at best they list sometimes (not always) the numbers of new Quality Seals. Quantitative assessments of quality level (by industry or product group — not to mention the quality of life) were not cited even once!

It is a good thing that qualimetry topics are dealt with by hundreds of scientific papers, including more than 80 monographs and that special subject headings are found in catalogues of some of the largest libraries in Russia: the National Library of Russia, the GPNTB, the Institute of Scientific Information in the Social Sciences and others, and that articles on qualimetry are included in the Greater Soviet, Russian and Economic encyclopaedias.

It is to be regretted, however, that the potential of qualimetry is often badly underestimated and that qualimetry proper is treated very narrowly. It is either invoked in connection with evaluating the quality of products only and not any objects, phenomena or processes, including the quality of life (the Greater Soviet Encyclopaedia approach) or it is considered merely as an element of quality control (according to the National Library subject catalogue).

On the positive side, a number of colleges in Moscow, Kiev, Nizhny Novgorod and Kaliningrad have issued learning aids on qualimetry for their undergraduates. Still, these institutions constitute a negligible proportion (less than 1%) of all of academic institutions in which such texts would be useful. The same is true for short qualimetry courses occasionally offered in some technical universities. After all, the mastery of qualimetric techniques could be very useful in the future careers of many college graduates, especially in the engineering, design, economy and managerial professions.

In this regard it should be noted that the first step towards recognising qualimetry as an important element in management training was made in 1995. Two State Standards for the college training of general managers were adopted, which decreed that students specialising in Quality Control must be taught the discipline of Qualimetry.

On the surface of it the biggest advances of qualimetry have not been in the fields of science, education or information, as mentioned above, but in product quality assessment (mainly in the framework of quality control and product quality certification systems). In this aspect, numerous industry-specific quality assessment methods have been developed, and on this basis, the quality category certification of products (including the Quality Seal certification). Thus, quality quantification (i.e. qualimetric) methods have become a routine tool in the product quality improvement efforts. All this would appear to be quite satisfactory…

In fact, not only is there no reason for satisfaction, but on the contrary, one notes with regret that the situation with product quality in general and with the use of quantitative evaluation methods in particular, instead of improving has shown a strong tendency for degradation. Let us explain this statement using just one case in point relating to a relatively recent campaign to increase the share of commodities bearing a Quality Seal.

A product assigned the Quality Seal was supposed to meet worldwide quality standards and thus be competitive in international markets. It was logical to assume that products bearing the Quality Seal were perfectly exportable. It would follow that the greater the quantity (in absolute and relative terms) of Quality Seal products being turned out the greater — other things being equal — should be their exports.

In reality the opposite was true. From the late “70s to the mid-80s the Soviet Union dramatically (by an order of magnitude) increased the number of articles that received the Quality Seal. Their number shot up to about 100,000.As for relative indices, according to the Soviet Central Statistical Administration, about 45% of all certifiable products turned out in 1986 bore the Quality Seal. Moreover, there were entire industries in the U. S. S. R. (such as construction and road machinery, and the electrical industry) in which the percentage of products awarded the Quality Seal was as high as 60%!

What about the exports that, apparently, had to grow too? The share of machinery and equipment in the Soviet exports to capitalist countries instead of growing was actually falling: to 5% (and later to 2%). Speaking of high-tech products, they amounted to only 0.23% in the Soviet trade with the West in 1985 (the situation is still worse today).Thus a paradoxical situation arose: as the share (and the absolute volume) of Quality Seal products increased, their export actually declined! There is only one rational explanation for this paradox: the method by which quality was measured (and the Quality Seal was awarded) was imperfect, to say the least. They allowed an upward bias in the true assessment of Russian-made products, leading to self-deception. (What exactly was wrong with those methods and why it was so, will be discussed in a chapter below).

To summarise our analysis of the current state of qualimetry in Russia, qualimetry is developing on both the theoretical and practical levels, but to a much lesser extent than it can and should.

1.1.3.4. Qualimetry Beyond Russia Today

As for the current international practice of quantitative evaluation of quality, when it comes to applied qualimetry, the consumer’s need for qualimetric evaluations of goods and services is met by specialised journals, which regularly provide quality ratings of similar consumer goods of different manufacturers available on local markets.

Some of these media are specialised in certain product types, e.g. the British Which? Car Magazine. Others, like the German Test, the French Que choisi or the American Journal of Consumer Message, provide qualimetric information for a particular type of product but also across the whole spectrum of consumer goods.

These publications have a fairly high circulation. For example, German magazines containing quantitative estimates of the quality of consumer goods have a circulation of about one million. German economists say that the comprehensive character of this information, its ease of access and its availability in quantitative form help the average consumer to takes bearings in today’s market. It is also a powerful incentive for manufacturers to continuously improve the quality and reduce the production costs of their products. In this respect, the presence of this kind of information (which is essentially qualimetric even if it is not called in that way) is seen as one of the factors in the steady scientific and technological progress in German industry.

Regrettably, nothing like this is found in the Russian market today, with the possible exception of quality ratings of Russian and foreign videos and movies, which are periodically, published in the journal Video-ACC or sporadic reprints from the German Test, published by the Russian-language journal Spros (“Demand”). This lack of qualimetric information about products available on the domestic market is not due merely to a lack of choice; it is caused mainly by the deep doubts given by the majority of Russian economists and managers regarding the possibility of obtaining and using such information.

As for international research in theoretical qualimetry its findings appear mainly in periodicals devoted to utility theory, operations research, decision theory, techno metrics or benchmarking. It should be noted that the term qualimetry is not used there very often or used in a somewhat peculiar sense. For example, a group of French researchers printed in the journal Epure (1994) a paper describing an instrument for measuring various characteristics describing alternating current quality (voltage stability, frequency stability, etc.). They called it, the Qualimeter.

1.1.3.5. The Future of Qualimetry: Developing in Breadth and in Depth

Now, what is the future of qualimetry? Let us decide in advance the kinds of future we have in mind. Talking about a short-term outlook, it is not very interesting because it is separated from our time by only three — five years. If we consider a long-term perspective, the uncertainty of our forecast will grow very much. Therefore, it seems to be most appropriate to give a medium-term forecast of the future of qualimetry.

We consider this problem, firstly, in relation to applied qualimetry, and secondly, in terms of three critical aspects: expanding its scope of application (by industry sector), the deepening of analysis (the extent of coverage of problems addressed by an industry) and improvements in quality evaluation techniques.

Extending the Scope of Application of Qualimetry

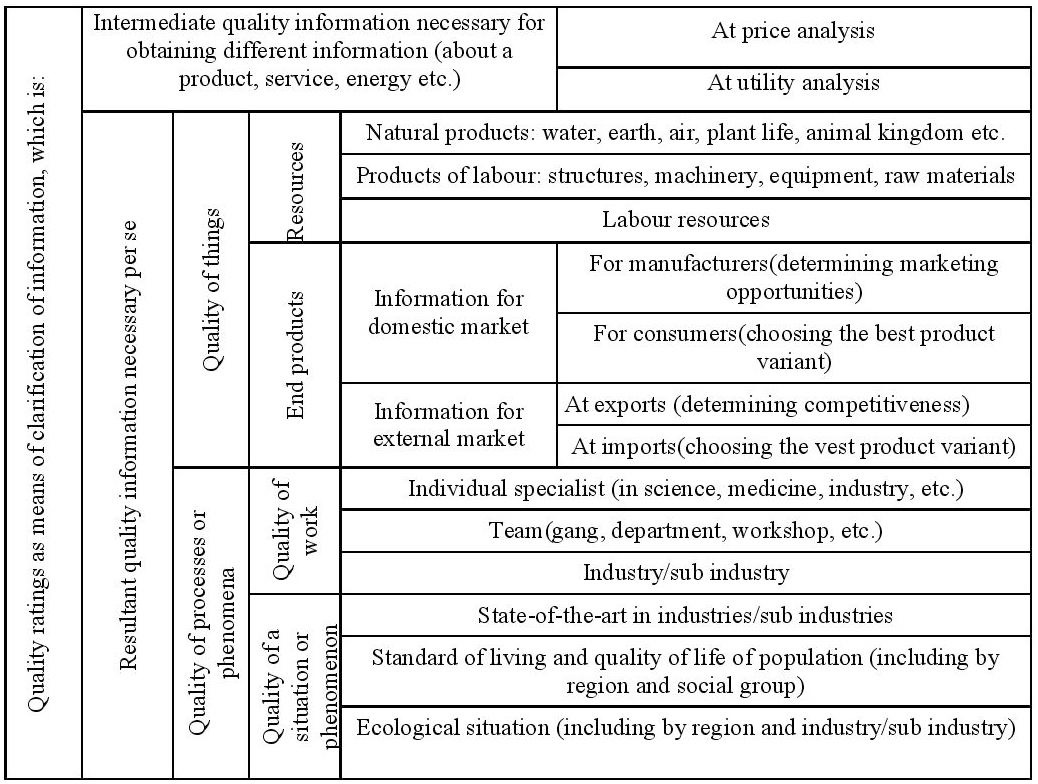

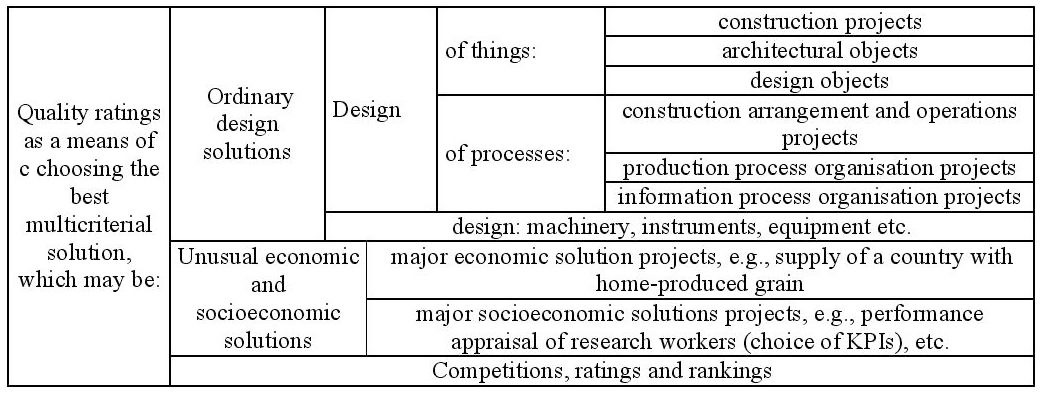

In contrast to the current situation there is a very strong reason to believe that the area of application of qualimetric analysis is going to get much broader. Having said that, qualimetric information will be used to address two broad classes of problem (for briefness, they are described in tabular form):

— To evaluate quality as a means of ascertaining the information used (Table 2); and

— To evaluate quality as a means of choosing the best solution to a multi-criterion problem (Table 3).

The information listed in the tables does not seem to require further explanation.

Let us consider the possible course of development of qualimetry as exemplified by the use of quality ratings as a market adaptation tool and a market mechanics element.

One of the important uses for qualimetric information is its adaptation to the needs of market participants:

— Manufacturers of goods and services;

— Vendors (procuring and trade agents);

— Purchasing firms; and

— Consumer societies (associations) as spokesmen and advocates of individual customers/consumers.

The literature of qualimetry has identified and classified 44 kinds of qualimetric information of benefit to one or more market entities. These kinds are arranged in tabular form under six headings: 1) analysis of simple properties of products; 2) analysis of complex properties of products; 3) analysis of product quality; 4) analysis of the price-quality relationship of products; 5) analysis of product competitiveness; and 6) analysis of the quality of manufacture of products. Since all of these kinds of qualimetric information have been described in periodicals (see, e.g., [6]), their consideration here is limited to the above notes.

Let us mention one more aspect of the future of qualimetry. Whatever form of distribution should evolve in the future (other than today’s normal shopping and services) — e.g., the selection and ordering of goods by e-mail, the provision of services at the customer’s convenience, the recognition of the customer’s every wish, etc. — it is always desirable that the consumer before purchasing any goods or services should have at their disposal not only quantitative data about their price (and operating costs if applicable), but also about their quality.

Moreover, this qualimetric information should not only be full and comprehensive (i.e. quality as a whole and its component properties such as reliability, functionality, user-friendliness, etc.), not only comparative (i.e. such that allows to compare the quality of different goods or services having the same purpose), but also ineligible to the ordinary consumer who is likely to be a non-expert. At the very least this kind of information should be included in the label/price tag/passport of a product.

1.1.4. Qualimetry: An Independent Scientific Discipline

Before showing the relation of qualimetry to other sciences we will analyse whether qualimetry is an independent scientific discipline; and if is, where is its place among the other scientific disciplines?

Unfortunately, in the professional literature there is no clarity with respect to the necessary and sufficient conditions (criteria) for delimiting a science from other human cognitive activities. Different sources treat these conditions differently.

To summarise current thinking on the criteria to be met by a scientific discipline, here are the most frequently cited ones: a subject of inquiry, an empirical (“prescientific”) history, a theory, a range of problems, a conceptual apparatus, and verifiability of findings.

Let us examine qualimetry in terms of meeting each criterion.

An independent subject of inquiry. Quantitative assessment of the quality of various objects (things or processes) is an independent and very important problem, which is the subject of inquiry of qualimetry. There are several scientific disciplines concerned with the quantitative study of objects in a way related to quality, such as utility, value, performance (as discussed above). But “quality” is not synonymous with utility, value or performance and for that reason it is studied within the framework of an independent scientific discipline.

An empirical (“pre-scientific”) history. Before 1968 (when qualimetry began to come into its own),hundreds of techniques for estimating the quality of various objects had been developed and applied in the U. S. S. R. (Russia) and internationally. But since these methods are usually developed on an empirical level, without a common scientific basis the period up to 1968 can be considered the “prehistory” of qualimetry.

Presence of a theoretical framework. There is an intuitive understanding of the necessity for this criterion, which is sometimes formulated in an explicit form. We note in this connection that the basic tenets of the qualimetry theory have partly been published in several monographs.

Presence of specific problems. It is true of any evolving science that once some problems are solved they are followed by other problems, which may be more numerous and complicated. This situation is typical of qualimetry. The further it develops, the greater the number of problems related to its future research areas that come to life. To illustrate, one of the earliest papers on problems of qualimetry identified eight problems whereas in more recent studies their number arose to 17, and later research on one of these problems singled out 26independent sub problems [7]. Thus, the existence of qualimetry as an independent scientific discipline is fully justified in terms of the quantity and complexity of the problems to be addressed.

Availability of a specific conceptual apparatus. Science in general and a single scientific discipline in particular, area specific kind of human activity. Its specificity shows in the fact that virtually every independent scientific discipline has a terminology, a conceptual apparatus and a language that are more or less specific to it. Qualimetry fully meets this criterion: its terminology is quite specific and not normally used by other scientific disciplines (or used in a different, non-qualimetric sense). This is confirmed by several Russian state standards for qualimetry terms.