Бесплатный фрагмент - Digital transformation for chiefs and owners. Volume 2. Systems thinking

Foreword

If you are reading this book, you probably already understand what digital transformation is, why it is needed, and you have the realization that change is indispensable.

As I said in the first book, digital transformation is a management tool and a global redesign of the business model and the entire management system.

But what do you think I face personally in life? It is banal with the fact that there is no system, but there is either complete chaos and dependence on personalities (at best), or bureaucracy with the suppression of any personalities.

The book will focus on the implementation of a systems approach to management, without which any transformation will be a simulation.

I do not insist on the truth in the last instance, but every time such an approach was applied at least partially, the result amazed even me!

Do you think it’s possible from a community where no one wants anything to build a team with exemplary discipline to triple their productivity in three months? I will answer «yes» because I have achieved this result.

But to do that, first person involvement is needed. And without accumulated dissatisfaction with the situation and political will, all other manipulations and tools are meaningless.

We will go through the areas of the system approach, find out what key tools are needed for its implementation, what global practices already exist, and explore practical cases.

Therefore, what is the systemic approach I am promoting?

It is built on a combination of:

— Lean Manufacturing

Its mission is to continuously improve, eliminate losses, including through the use of digital technologies. Allows you to determine the objectives of the implementation of the figure, to build tactics.

— Project Management

Allows to minimize risks and budget.

— Using the product approach

Digital transformation must be accompanied by the creation of new products. Additionally, without the basic tools of food management, it’s almost a guaranteed failure. Additionally, then you won’t just be disappointed, you might end up on the verge of bankruptcy.

— System constraint theories

It allows for prioritization so that efficiency gains can be achieved with less investment. For example, a project for 3 million rubles, aimed at increasing productivity by 3 times, when applying the theory of system limitations, allows to reduce the budget to 1 million rubles, while receiving a 2.5-fold increase in productivity.

— Introduction of Changes

Digital transformation is about people and processes. The application of the main tools for implementing changes minimizes risks, resistance and the likelihood of a setback.

— Managing communication between units

Communication between units is a secret ingredient of both success and failure. Digital transformation is absolutely about the same — the ability to sit down, negotiate, hear each other. In my practice, all crises or problem projects / companies have one problem on the basis — cannot agree or do not hear each other, especially the top managers of their subordinates.

In general, working with SEO’s is very difficult. As a rule, these are people so-called «E-type» by Adises: entrepreneurs, bright and strong personalities, authoritarian, do not tolerate opinions different from their own.

These qualities help build companies, overcome the first problems — thanks to stubbornness, perseverance, authoritarianism, but then it begins to hinder business growth.

From this there is such a principle in management: centralization of power is needed at the start and at the collapse of the system, but for development decentralization is needed.

Which means the decision maker needs to change. However, when this man reaches the heights, he becomes stale, loses his former flexibility: he has gone the way, proved his worth, and now it is very difficult to recognize the need to change for further growth or the correctness of others’ opinions.

Now, can you imagine how a strong person like that would learn to detach from manual control?

— Using Digital Technologies and Data for Decision-Making

The first book was essentially devoted to this section. Digital transformation involves the active use of digital tools and analytics to minimize risks, create new products.

— Regular management practices

Digital technology will not fix chaotic controls, blurred targets, toxic communication, lack of control points. These are only tools that need the master’s hands.

— Working with strategy, organizational structure and business processes

Organizational structure and business processes are the foundation of an organization that supports the achievement of strategic goals. But they (structure, processes, strategy) are not eternal and must change over time.

Digitalization and digital transformation must become your strategic goal in order to «top» initiate all other changes.

Org. The structure aims to achieve the goals of the company by providing the necessary people with resources and dividing areas of responsibility.

When changing goals, strategies, available technologies (resources), you need to change the structure, allocation of resources and authority.

Therefore, you can shape the book’s message: digital transformation is one of the tools to achieve the goal; you can’t just implement one tool and hope that it will dramatically improve efficiency — you need integrated work.

Is it possible to master the whole approach one person? With due perseverance and consistency for 10—15 years — yes. Of course, no one has that much time, so the only way is to form a team with the right competencies.

Therefore, this book will be useful for both top managers of large organizations that can build work with middle managers, and managers of small companies.

P.S. This is the second edition of the book. In addition to minor adjustments to the original material, it is supplemented by two new chapters — what to teach staff and to what level, and a roadmap for digitalization and digital transformation. Practical examples of sharing systems approach tools have also been added.

Chapter 1. Organizational Structure and Business Processes

We will start with the organizational structure and work with business processes. If you translate into everyday language, org. The structure is the skeleton of the company, and the described, streamlined and efficient business processes are the nervous system.

The organizational structure is the basis for the management system. It achieves the company’s goals by providing resources to needed people and delineating areas of responsibility.

Additionally, when you have new technologies, changing goals, the company «matures» and moves to a new level, then business processes with organizational structure should change.

A clear and visualized organizational structure is a MUST. In my practice, there has never been a single case of a company operating smoothly without the organizational structure described, accessible and understandable to all.

Most often I observe the following:

1. There is no organizational structure. This is acceptable if you are 2—3 people, you are a strong manager and you have a strong team, you know how to negotiate among themselves. Otherwise, it is a realm of chaos. Even if you have the processes described.

2. The organizational structure is on paper, but in life quite differently. As they say, «waiting is reality».

3. There is an organizational structure, but it has no information about functions, powers, responsibilities. It’s not synchronized with the company’s goals, it’s not confined to team-building.

You can work without a description of business processes, but if there is a clear structure, with a description of functionality, key indicators and target product, it allows to radically improve efficiency and productivity, to establish a team relationship. Here the business processes described will allow to achieve even more efficiency, and subsequently to engage in automation and digitalization.

However, the business processes described will not work without a clear and understandable organizational structure, because you will not have a skeleton.

Types of organizational structures

It is now customary to identify several types of organizational structures:

— linear;

— functional;

— linear-functional or linear-stacked;

— divisional;

— market;

— matrix;

— food.

We’ll tear down each of them.

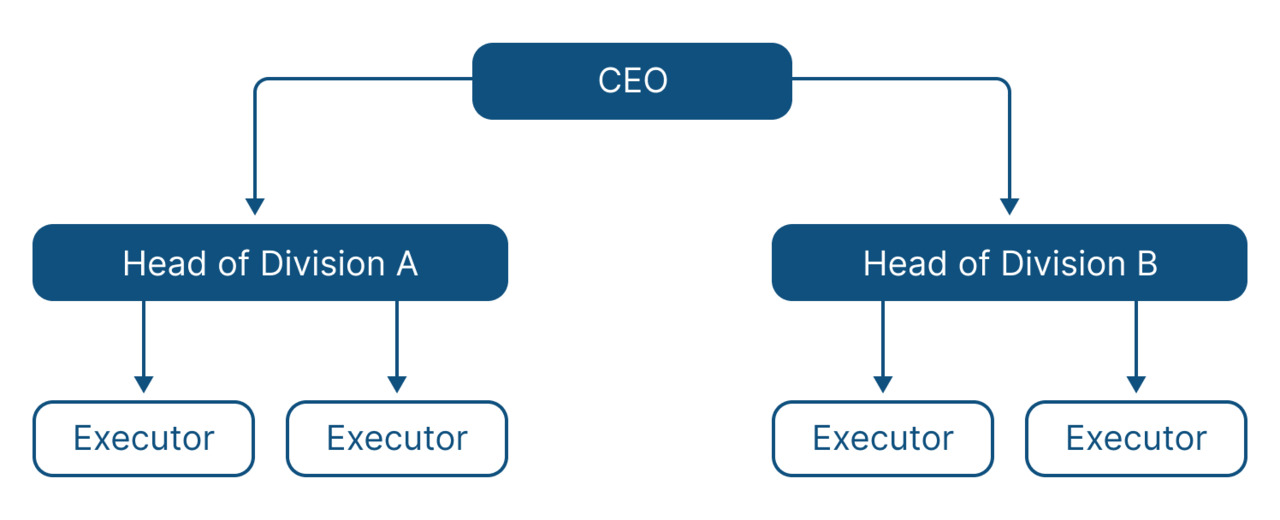

Linear

The simplest model: straight and hierarchical. Key decisions are made from the top, and they go down without any separate functions: sales, marketing, production. Suitable for small companies with simple manufacturing technology and minimal need for additional features.

Pros:

— simplicity and speed of management decision-making;

— quick reaction to instructions and orders;

— a clear allocation of responsibilities and responsibilities;

— discipline.

Cons:

— overload of managers;

— concentration of a large amount of non-core work on managers;

— weak relationships between the performers;

— with the growth of the organization, the number of management levels increases rapidly, which reduces the flexibility of the company and the speed of response to changes.

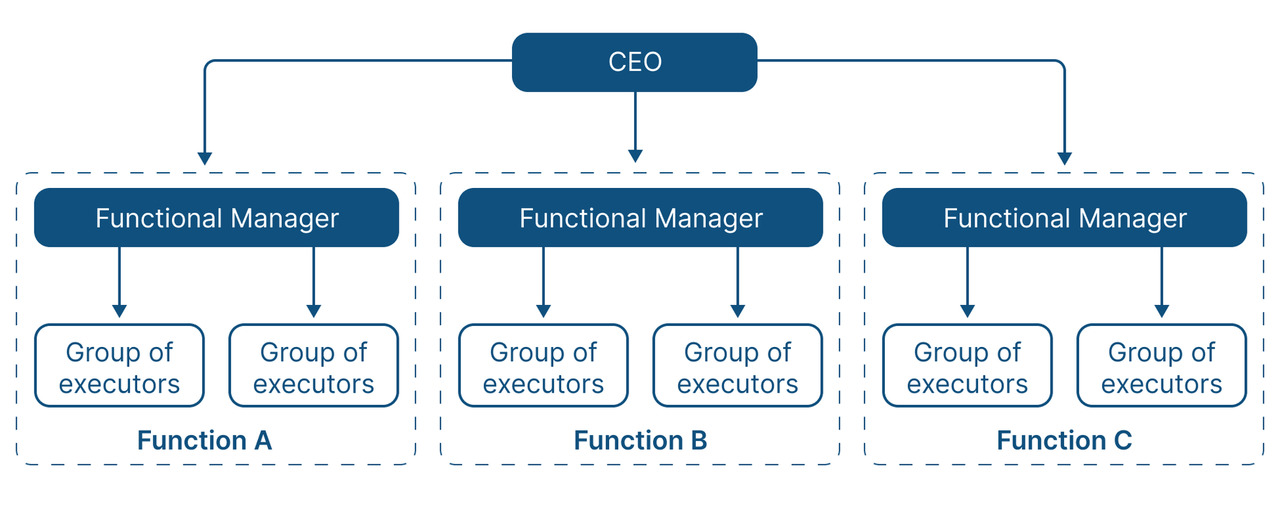

Functional

The division of responsibilities is based on the functions performed: production, sale, marketing, accounting and tax accounting, financial management. At the end of the day, everyone takes his own direction. Optimal for small companies that work with one product, but require already more complex production organization.

Pros:

— narrow specialization of directions — increase of productivity and quality;

— a clear allocation of responsibilities;

— exempting line managers from functions outside their competence;

— no duplication of functions (if business processes are built).

Disadvantage — the larger the company and the larger structure, the more difficult it is to organize the division and communication between the departments, while retaining the team interaction. Bureaucracy is beginning to flourish.

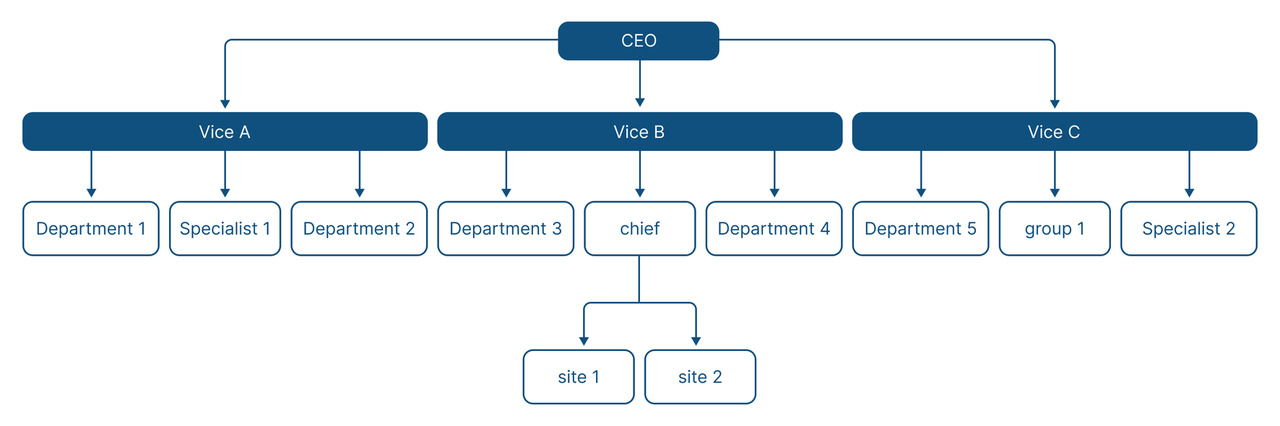

Linear-functional

The combination of distribution of linear and functional problems. In line management, there are production units where the manager is responsible for everything and support functions are performed by functional managers.

An example is a production hall with a technical director who is responsible for the work and discipline of the staff, the state of technology, productivity — in general, for everything. At the same time, there is a management apparatus, headquarters, where all support functions are carried out: procurement, search for contractors, travel arrangements and so on.

It is the most common among medium and large organizations, where people from a few hundred to a couple of thousand. Optimum in a stable environment: standard production processes, stable demand and external environment, without the need to implement a large number of projects and create new products.

Pros:

— narrow specialization of directions — increase of productivity and quality;

— the ease and speed of managerial decision making;

— quick reaction to instructions and orders;

— minimizing duplication of work.

Disadvantages:

— high, sometimes unjustified, administrative staff costs;

— the growth of bureaucracy when functional managers are more interested in their security than in overall success.

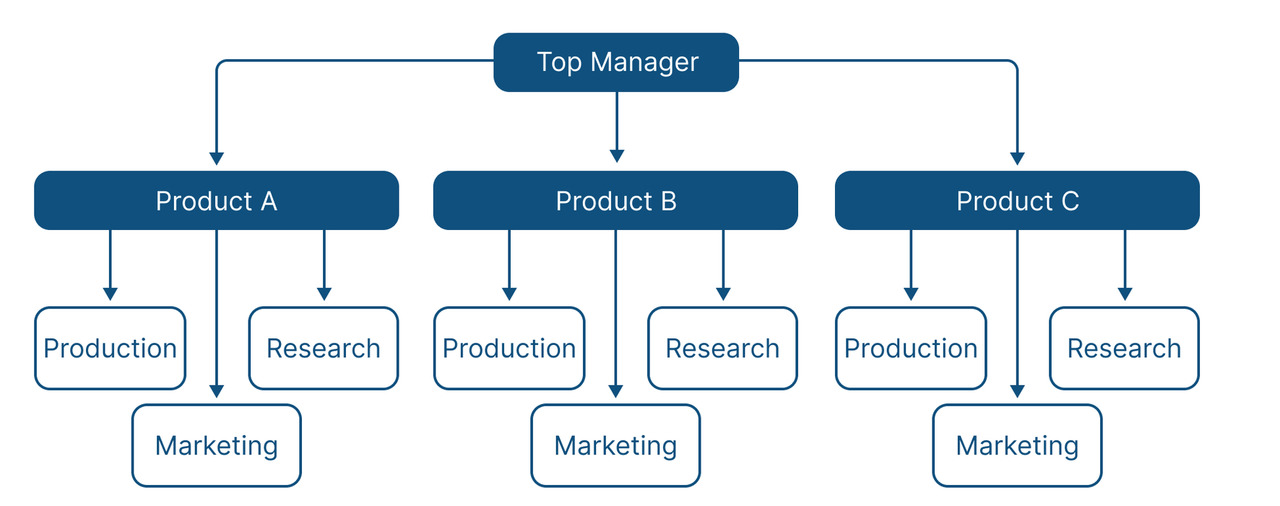

Divisional / Market / Grocery

Similar to the linear structure, but the divisions are structured according to the principles of product or market separation. Optimal for companies with a large number of markets and heterogeneous products. For such enterprises it is necessary to create individual basic business processes for each product / region: supply, production, marketing, sales.

Pros:

— flexibility — individual strategies and business processes can be developed for each product / region;

— easy coordination and coordination of management decisions;

— high speed of response to emerging problems;

— high performance and management quality thanks to specialization.

Cons:

— as in previous models, there may not be a common goal, each for himself;

— unhealthy competition between structures and directions, growing political differences;

— different productivity;

— low budget efficiency.

Matrix

It is a complex model designed primarily for project implementation. A staff member may have multiple supervisors, and project and resource management is entrusted to the project manager / office.

Sometimes attempts are made to create hybrids of linear-functional and matrix models, where the implementation of projects is entrusted to functional managers. For example, an industrial safety system is being introduced and the head of the industrial safety department becomes.

Pros:

— is responsible for the implementation of a manager with high professional competence;

— the project manager can influence the situation at his own discretion, without unnecessary control (but this is rare).

Disadvantages:

— complexity in the implementation of projects and allocation of responsibilities, conflicts of interest, requires a high level of competence at the manager;

— low performance;

— duplicate functions.

I will give an example of the implementation of this approach.

Integrated corporation with central apparatus in Moscow and a large number of regional units with linear-functional structure.

The central office initiates the implementation of a complex IT system that covers a large number of business processes and requires the inclusion of both technical and financial and HR. In each regional division a responsible manager is appointed and fun starts… The manager is responsible for the whole project, but the resources and authority to manage other people’s (financial, HR) blocks are not, and the desire of others to change at will is even more so. The curator in the central apparatus is not all-powerful and is also located within the functional subdivision. In general, to implement such a project — a hell of a quest.

Matrix structures can also be divided into weak, strong and balanced.

The weak

Weak matrix structures are used when there are many projects, but they are small and not routine, not critical for the company.

In a weak matrix, the members of the project team are managed by functional managers (Chief of Industrial Safety, Repair Planning, Procurement) whose authority is limited: each is responsible for his or her direction.

There has to be a project manager who reports to management or, in this case, central office, gets his tasks. Tasks are then decomposed into smaller tasks and assigned to functional staff. But in fact, it has no powers and no resources. It is fertile ground for conflict.

It is also possible to have «forwarders». These are people in functional areas who disseminate information but have no authority — informal leaders of opinion.

As we can see, this approach is not applicable to our large-scale project. Unless we have very charismatic and strong project managers on the ground.

The strong

Differ in that the implementation of such a project may not be one, but several managers, or the manager and team, and they have much more authority. They can now not simply hand over tasks, but also give orders, require tasks and project reporting from functional managers. In addition, the project team may not be a permanent part of the functions, that is, it is possible that they will deal only with the project, plus they can search for contractors or order raw materials.

For our conditional IT system implementation project, this approach may be redundant. Although, perhaps, it will increase the chances of success, but such implementation comes out very expensive.

Balanced

In this case, the project manager is appointed from among the staff and, better, from the functional managers. Here he can set tasks and monitor their performance. However, it is likely not to be exempt from its operational tasks and to be unable to manage its own resources.

It is worth noting that this is the most difficult option to implement, as it involves the largest number of assigned roles, moreover, there may also be issues with subordination and, consequently, matrix conflicts.

Summary

We have dismantled the main types of org. structures. It would seem, choose the right, suitable for your company, and everything will be fine. Alas, it is not so. It is important to distribute functions and powers correctly, to identify a key product of the activity, to choose the people for whom this work is suitable psychologically, and also to build communication between them. That is why I always speak of a systems approach: it is impossible to implement any one tool — integration is needed.

Besides, as we can see, already at org level. The structure is related to the number and size of the projects implemented, that is, there is a close interweaving of work with the organization. structures and project management, they become inseparable.

To consolidate all practice, I propose to look at one real example with two structures of the same type, but with a completely different substance. Since the organizational structure in the book is almost impossible to display, everything will be available via QR and the link below.

Additionally, it should be remembered that with the development and organization. structure, and distribution of functions should change.

In addition, there is a trend in the world to avoid large bureaucratic structures. Why? In addition to economic factors and long transmission chains, this is a breeding ground of irresponsibility. As a result, there are a lot of people in charge, but all are formally covered up, and Ivan’s locksmith is to blame.

Here is a practical example: the repair of industrial equipment has been exceeded due to a chain of events: could not form a brigade because one of its members failed the exam because the head of the service could not form a commission for the exam, because two people on the commission were on vacation… Additionally, nobody seems to blame, but in the end, the object is worth… Until the Chief Engineer, in a terrible curse, corrects the situation in the simplest but not the most obvious way for all listed.

This case isn’t really just about an organizational structure where, under the guise of collective responsibility, the mess is going on. It is also about the corporate culture, which is based on the direct execution of rules (the culture of rules), and formed it the same chief engineer and his predecessors.

Could even in this structure avoid these problems? Of course! With proper work of managers, building of control points, informal communication, leadership qualities of this situation would not be. Additionally, here the main thesis that will go through the book — it is impossible to build an effective business system with one tool.

Main approaches to modelling and description of business processes

Introduction

In addition to organizational structures, there is another key area — business processes.

A complete list of almost all approaches to description with illustrations, display examples and videos available IT-solutions is provided by QR-code and link below.

Here I will consider the most common ones, answer who they are, show what I observe in life, use it myself, and summarize — what is more important: structure or business processes?

I understand that all this may seem boring, but in practice I have learned one simple rule — there is nothing worse than arguments «it is so clear», «it is too simple». Always, when I have met such arguments, this has not boded well. These theses are harbingers of chaos and disorderly problems. So, I chose this structure: first a little bit of general theory, then practice and working principles.

Basic approaches to the description of business processes

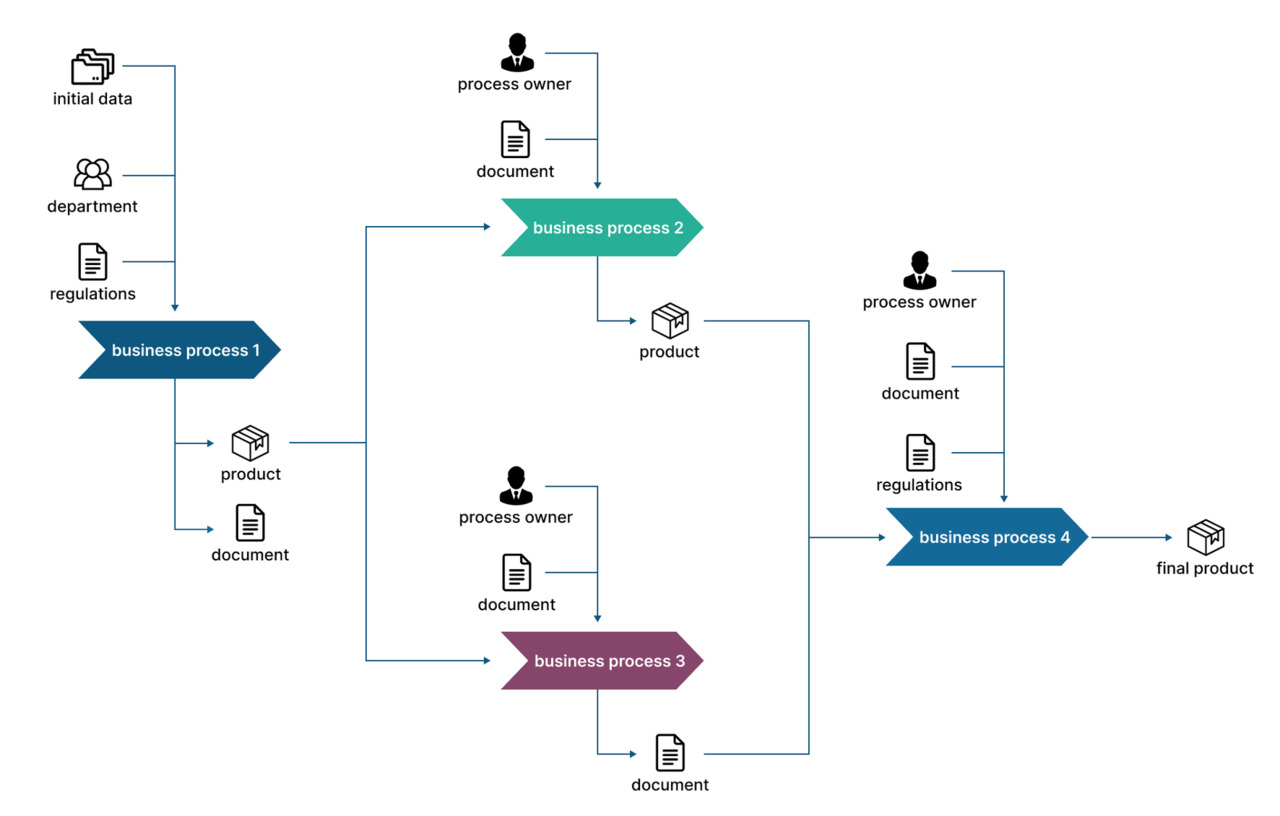

A business process is a certain algorithm of interrelated actions of people and IT systems, which is aimed at transformation of «raw materials» into «product» or result.

For example, the business procurement process involves the following stages: requisition, sourcing, solicitation, delivery of materials, delivery to the requisitioner. But each stage is also broken down into separate business processes. Therefore, you need to understand that the description of business processes is almost infinite task, and you will need to choose the level of detail, at which you say «all, enough». The lower the level of command competence, the more detailed should be made the description. Or you need to train the team, but then you have to grow as a leader. Smart personnel will not tolerate treatment as fools.

Conventionally there are several approaches to the description of business processes:

— Value Chain Diagrams (value added chain diagram, VAD);

— SIPOC;

— Event-driven process chain (EPC);

— BPMN 2.0 (Business Process Model and Notation 2.0);

— Flow Charting (Process and Procedure notations);

— IDEF (Integrated Definition Language);

— UML (Unified Modeling Languages);

— VSM (Value Stream Mapping);

— ARIS;

— DFD.

Value Chain Diagrams (VAD)

An approach that allows you to describe at the highest level the key activities of the company and departments, show the relationships between them. Here the focus is on graphical display of business processes that create value for the client.

That is, it is a kind of «master model», which gives the whole team an understanding of how its work affects the company as a whole.

Rules of construction of VAD-model of the value-added process:

— To begin with, it is necessary to identify the key tasks of the company or division that characterize its activities.

— Their logical relationship is then constructed.

— The owner and the unit responsible for the process shall be identified and specified.

— The main documents regulating the business process are indicated.

— Additional information and resources required to complete the business process are indicated.

— Links to lower-level diagrams (VAD or EPC) are attached to each upper-level business process.

SIPOC

Approach to the description of business processes, which is a tool in lean production. The title reflects the whole essence of the approach, which focuses on five components:

— Supplier (supplier) — person or company that supply resources for the execution of the business process (production, money, materials, data);

— Input (input) — resources for business process: materials, money, production capacity, data);

— Process (process) — all those tasks that allow the result of the work to convert the raw material into the final product;

— Output (output) — products of business process activity;

— Customer (customer) — recipients of services, those who use the product of the business process.

The SIPOC business process is described from the end:

— Identify the customer of the business process;

— Describe the final product (output) that the customer needs;

— Highlight 5—7 key business process operations;

— Identify the necessary resources (input) for the business process;

— Identify the providers of these resources

The key advantage is the speed of description, the ability to identify unnecessary steps that do not create value. This approach is somewhat similar to VAD and is a top-level description. Allows to identify the most obvious losses.

Process Event Chain (EPC)

This approach describes business processes in the form of individual stages/steps of the process and events that initiate these steps, that is, the structure of the «event — function — event» is obtained. This method is well suited for standardizing business processes and analysing the flow of documents and necessary information throughout the business process.

Main elements of the description:

— An event is something that creates the need for action.

— Function is an action to get the desired result, in response to an event.

— Performers are those who perform the function, including approving, coordinating, etc.

— Resources are all that are necessary for the implementation of the function: money, information systems or individual modules, documents, operational risks.

Unlike the previous approach, where the beginning was on the left and the finish on the right, everything starts from the top and goes down.

Description algorithm:

— Determine what we have and what we want — boundary events.

— Describe intermediate events that are inside this process and what tasks need to be performed / to implement functions.

— We add all the necessary information on implementers and resources.

— Analysis of the completeness and quality of the scheme, whether it takes into account all variations and sub-processes. If necessary, make additional schemes for sub-processes. However, here I recommend always remember the rule from the first book — one scheme, one sheet or screen.

Plus, the approach — the ability to then create clear rules in the form of text or table. This notation is quite common, especially in large organizations, because on the one hand it standardizes the description and on the other it is quite flexible. For example, it is often used to configure ERP systems.

BPMN 2.0 (Business Process Model and Notation 2.0)

BPMN — today a de facto standard in the description of business processes with a wide set of graphical elements for modelling. If for ordinary users and managers this is not the most convenient approach, then for business analysts it is a mandatory tool: to describe within this approach a fairly large process on one sheet will be difficult, in addition, the approach is quite strict, However, this is more detailed and it is easier to identify local errors.

An example of the description in this notation below.

What I observe in life and apply myself

Unfortunately, in 99% of companies or no description of business processes, no top-level or even more detailed, or it is formally and made to tick, and in life everything works differently. Additionally, as long as the organization is small, 5—10 people, it is not scary. But after it begins to grow, chaos becomes more expensive pleasure.

In my life I adjust to the task, the level of maturity of the company and employees. It is mainly a hybrid of EPC and Notation Procedure (more on QR code at the beginning of a section), and sometimes a simple flowchart.

Summary 1 of the chapter and recommendations

More importantly: organizational structure or business processes described? Where to start? This is a perennial discussion. My personal opinion: as long as the company is small, it is becoming or restructuring, the selection of the business model that will give a result, you can do without business processes. If you have an organizational structure, clearly defined functions, a key product and, preferably, metrics (I do not make this a must, because I have seen isolated cases of a qualitatively developed system of key indicators), then you will not drown in chaos. People will be able to communicate and negotiate among themselves, which is a key element. I would even say that it is a useful exercise to first teach people to work together, sharing power, responsibility and resources, and then to implement process management. As a result, the work with the Org. structure will create a skeleton of the management system, including:

— ensure efficient use of resources;

— increase productivity;

— minimize the need for regulations, rules, detailed descriptions of each business process, in general, in the work with paper;

— minimize risks to the company, especially those related to dependence on individuals;

— reduce people’s congestion and turnover. Instead of one or two universal «working horses» there will be a distribution of tasks, the uncertainty that causes stress and burnout will be reduced;

— unload yourself as a leader: you do not have to often interfere with processes and understand conflicts, as the system will become transparent, everyone will understand their area of responsibility. It’ll be easier to pick up people and prepare job descriptions.

In addition, in the early stages, including the start of digitalization, your business processes will change too often, and constantly change and update them — too expensive a pleasure. Additionally, if you describe and «freeze», you lose the main advantage of the young team — its flexibility. The exception is critical processes with high risks and back-office processes, they are often stable and better dealt with initially.

However, after the initial stage is completed, it is necessary to engage in business processes. It is not necessary to fix everything and detail, but the most critical processes, where the risks are high, where problems begin to occur, should be described at least at the upper levels. Top-level approaches have the main advantage — speed and simplicity. And this will have an effect, and therefore, resources and motivation for in-depth work.

For grown-up companies there is another problem — bureaucracy. There is already a reverse approach — simplification of business processes. In general, as always, the search for a balance between chaos and entrepreneurship and order with bureaucracy.

As I said earlier, the right org is important. structure, proper distribution of authority, resources, responsibility and people, taking into account their psychology, system and personality balance. Additionally, if you listen to the classic science of Peter Drucker’s administration, you have to initially describe who you need, and then you have to choose the person for these tasks. This is the key message of his work «Effective Leader». But I have a slightly different opinion here.

This approach in a pure form is viable in an already mature company, where the requirements for candidacy are grounded, and the structure is balanced. In addition, such a company is attractive in the market due to the decent payment and the established reputation. If you are still young, you do not have a balanced system and/or you do not have a queue of applicants, then a certain flexibility is required. Yes, it is better to base on the principle of Peter Drucker, but the organizational structure needs to be adapted to the available resources and people, their psychological qualities, soft skills and competencies. That is, as usual, remember how to, but seek balance with what is.

This is basically the basic rule of life, and there is no ideal solution or methodology for either organizational structures, business processes, or project management approaches and so on. It is impossible to get rid of the psychology of people and technologies or tools to solve all problems, but to strive for an effective and autonomous system is necessary.

If you decide to approach the search for a new employee systematically: describe the functionality, requirements, its KPI, what characteristics should have, it does not mean that you will find the ideal, but it means that you are likely to find someone who will be useful to the company, will be suitable for its culture, although in some details will differ from the image of the ideal candidate.

How to build a suitable organizational structure? And how often to revise it?

I recommend the following algorithm:

— Define the goals of the company, its strategy: rapid growth, smooth, holding positions, scaling to new markets. It also determines which areas of the organization to focus on.

— Evaluate a company: what industry and its potential, what product, what technology lies at the core, and how often will have to implement projects, what markets.

— Assess available technologies and resources, including digital ones.

— Choose a structure and describe for each unit and position 4—6 key functions, target product, required competencies (professional, personal) and, where possible, available resources.

— Describe the main business processes, starting with the VAD-approach. Here you need to see the main stages of product creation, understand which of the participants in the process creates value and what.

— Assess: Do all these people and units create value? Where are the losses? What can be abandoned with digital technology or outsourced? If you only build a company, it will provide minimal costs, and if you transform, you will release resources to priorities.

Another recommendation: When goals are achieved or after the introduction and mastery of new technologies, revise your organization. structure. Or make it a rule every 6 to 12 months.

With regard to business processes, I can make the following recommendations:

— initially make a VAD-scheme throughout the company;

— prepare a process registry (first, second and third level processes, process owner, process participants);

— then take advantage of product management and system restriction theory to select priority business processes;

— it is also important to describe those business processes that are stable and are the best practice for others. Or, conversely, useful description of problematic business processes;

— does not need to describe every business process, only those tasks that are either standard or carry risks for business;

— begin to describe processes with approaches that you understand and who will use them;

— describe business processes so that they fit on one sheet A4 if you want to start the process, and in the notation BPMN if you want to analyse and optimize the process. Additionally, only after optimization do IDEF to deal with automation;

— describe the processes and prepare instructions or memos as if all the employees will leave tomorrow, and the replacement will come fools or 8-year-old children.

At the beginning of the book, I said that digital transformation should be your strategic goal, and therefore, this role should have a place in the organizational structure. Simply put, someone has to be responsible.

In general, I believe it is necessary to proceed from:

— your scale and availability of resources;

— the current level of digitalization and readiness;

— the limitations of the system (which will be discussed in the next chapter), global goals (to overcome the crisis, to ensure growth conditions, active growth) and objectives (to restore order, create new products, improve product supply).

There are many variations, and therefore, and possible structures. That is, to begin with, you need to pass a diagnosis. It is as with health: before treatment, it is better to undergo an examination and make a diagnosis, from which there will be a plan of treatment or recovery. But given that digitalization and digital transformation are strategic tasks, and the price of error may be too high, it should always be its driver.

If you are an entrepreneur or owner of a small business, it is better to find an experienced mentor who will help you to manage this direction, giving to outsource only some tasks on automation and software implementation. You can also find a team from the outside that deals with digitalization and turn-key digital transformation, with all the skills and necessary experience. The second option suits medium-sized businesses. But in any case, you have to understand automation, digitalization and digital transformation at least on a basic level.

If your business has grown from small to medium, in connection with which there are signs of chaos and lack of work with data, then you need to restore order and eliminate losses (in the chapter on thrifty production talk about this concept), remove internal restrictions, CDO 1.0 and 2.0 in data management. To do this, it is better to give the role of the leader of digitization to the operating director.

If the problem is a weak food supply, then this function should be given to the commercial director. In this case, it should be remembered that in any case to oversee this task as strategically important will be the director and/or the owner.

In any case, it is necessary to organize comprehensive training for a commercial or operational director. If digitalization is the responsibility of the Business Director, it will be commercially calibrated and aimed at increasing sales, which means that it will generate additional resources rather than processes and introduce a conditional electronic workflow just because it is necessary (by the way, the EDO can really bring huge benefits and eliminate just internal chaos and costs).

Well, if you’re a top corporate manager with resources, it’s best to have a separate division led by a CDTO (Digital Transformation Manager), which will build the methodology of the system approach and act as a centre of expertise in digital technology, processes, project management, product development. The team should necessarily include: a process specialist / business analyst (better couple), a data specialist, system analyst/architect, an IS specialist (to this we will dedicate the next book), a portfolio manager (if you train the staff, one is enough, if not, the project manager to each unit). If you put them in different units, these people will have to build horizontal links and matrix interactions. And this is longer and suitable only for mature companies, with respect in communications. If the company is less mature, it will result in an increase in the time. A weak system requires centralized control.

Key, I strongly advise against giving the digitalization and digital transformation function to the Director of Information Technology. After all, a rather limited number of IT directors can engage in process re-engineering (which is the core of transformation), approaches to project implementation, product development, has a customer focus, including to the employees of their company. For them, such concepts as UX|UI design of solutions and processes are distant.

It is necessary to pay attention to the IT departments themselves — to describe their structure and processes. Otherwise, with the increase in the number of IT tools, they will stop coping. You will either have to inflate their numbers, and they will become less organized (people will not understand who is doing what, there will be no training and commissioning processes). And/or everything will work randomly, especially technical support. And this is a direct way to discredit digitalization.

As a result, the main advantage of working with business processes and organizational structure — the opportunity to abandon expensive professionals, including IT developers. You will be able to focus on the selection of analysts (business and system) and trainees, who will grow under your company, and who will be 2—3 times cheaper than experienced experts. At the same time, it will be easier to manage them. At the same time, it will be easier to manage them, and the return from IT is higher, the cost is lower. You will also be able to build your work with data: what data is generated by the company, what is needed, who and why, and work with data is key in all digitization and digital transformation.

Chapter 2. Systems limitation theory

The second tool I want to share, and without which it is impossible to do business, is Eliyahu Goldratt’s restrictive theory.

The essence of the theory is to find bottlenecks, system constraints and eliminate them, while increasing the performance of the entire system. This approach also warns of the danger of excessive productivity of one element, i.e., at times the overall success requires reducing the productivity of individual units.

To understand the principle of this tool, consider two practical examples.

Practical examples

Example one.

You need to increase the productivity of the factory, let’s say, on the production of metal doors. You can approach this issue in two ways:

— reducing internal costs and losses by organizing lean production;

— through modernization and technical re-equipment, i.e. there is by removing technological restrictions.

Suppose the arrangements had exhausted their potential. You’ve digitized and visualized your processes, eliminated all the losses, and then you’ve measured the performance of the units, and you’ve discovered that the system’s limitations are now the paint shop.

Then you went to the production manager, and he brought you a list of things to upgrade.

According to preliminary calculations, 200 million rubles are needed for the modernization of the workshop, which will lead to an increase in productivity by 40% and a reduction in the proportion of rejects by 80%. Together, this will increase total productivity by 60%.

You then visualized the flows in production, modeled all the scenarios depending on the product line, and found the system’s limitations inside the shop. Help in this lean production (circle Tahiti Ono, elimination of losses) and mathematical modeling.

As a result, you saw that you can invest only 10 million rubles, and the productivity of the shop will increase by 35%, and the share of rejects will decrease by the same 80%. The total productivity of the enterprise will grow by 53—55%.

This is the principle of system constraint theory.

The second practical example.

A business venture where sales are more than successful. But its limitation is production capacity: production does not have time to process and release all the orders taken, and raw materials are purchased for them. As a result, we get:

— the stock of raw materials and semi-finished products is being overloaded, and storage capacity needs to be increased. This increases the cost of rent or new construction, requires additional staff, also increases the risk of damage to raw materials;

— the raw material begins to be stored longer in stock, which leads to an increase in frozen working capital and future losses. Some of it will go into marriage.

All these are losses in terms of economical production. Additionally, in the language of economists, it is frozen circulating funds, which is also very unpleasant. In addition, there are other effects:

— cancellations of orders, which are reputational losses, risks of penalties, plus raw materials need to be sent to recycling or «perpetual storage» due to the inability to apply it to other orders;

— deterioration of the KPI sales department and managers, which leads to conflicts between departments;

— will start to appear «urgent» and important orders, which is already interference in the production cycle and even more reduced productivity with an avalanche effect;

— increased pressure from owners on production, a further deterioration of the climate and an increase in staff turnover.

As you can see, a huge number of losses are generated, which we will talk about in the next chapter. They lead to a «perfect storm» and crisis.

This example is taken from real life. The company changed 8 managers and 90% of the production staff for the year, there were risks of penalties of 20 million rubles. And the limitation here was in the managers. Yes, the restrictions are not always technological, we will consider a detailed list below.

As a result, it was necessary to reduce the productivity of the sales department, to restructure production processes, and then to develop commerce again.

In terms of digitalization, the system constraint theory will help us to understand where the digit is originally implemented. And this will allow you to quickly feel the effect for a little money, which in turn will remove resistance from the team and will increase the amount of finance available for further changes.

In transforming and increasing efficiency, it is not only changes and technologies that are important, but also the point of focus. Additionally, eventually, it will increase net profits.

If we go back to the instrument, there are five so-called «focus stages» in the constraint theory.

5 steps — the essence of the whole tool

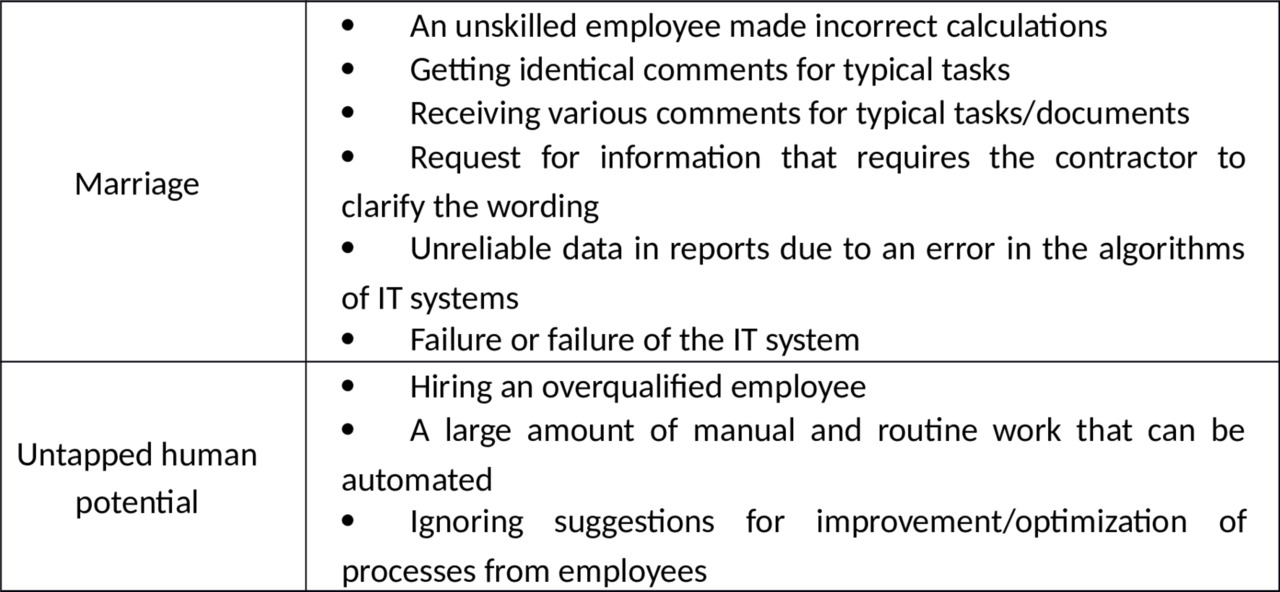

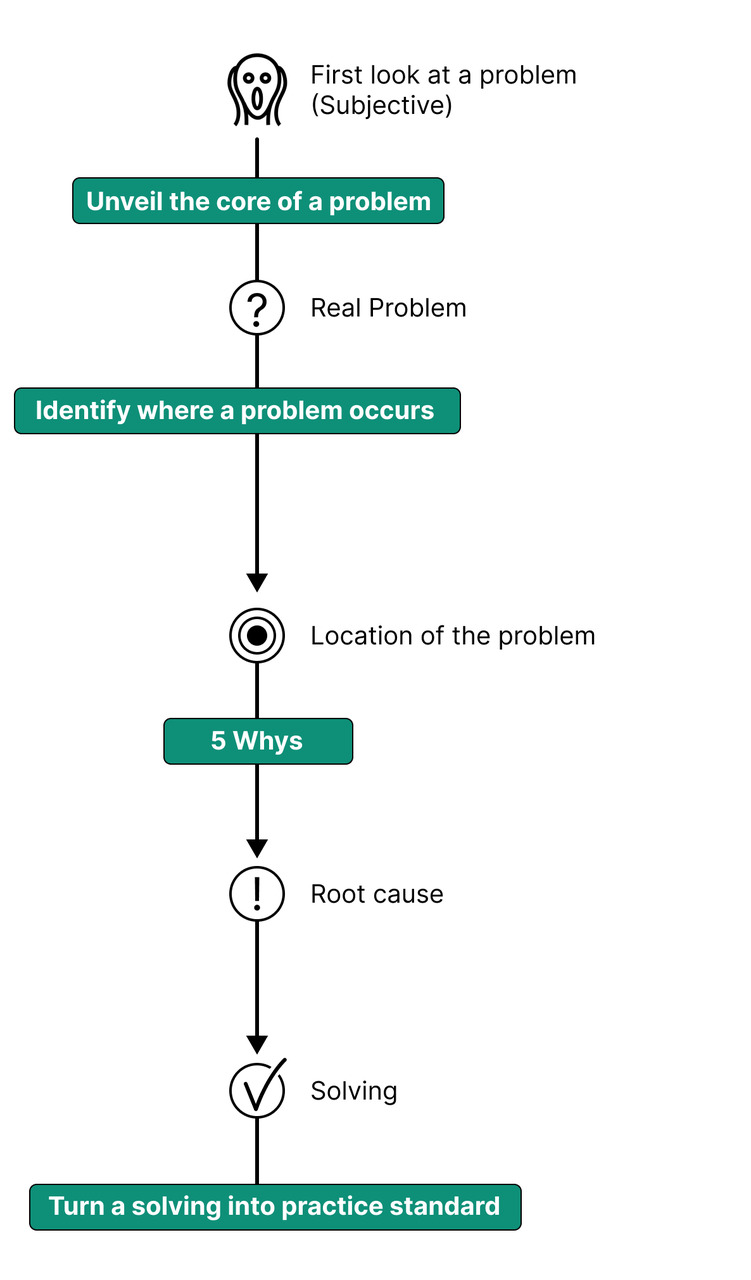

Step 1 — Finding a constraint.

Constraint is a weak link (resource, people, technology, materials) that hampers the effectiveness of the entire system. It comes in two types: internal and external. Example of the first — the capacity of the equipment, the competence of employees. External factors are the market, its competitiveness, saturation, capacitance, seasonality, purchasing power.

At this stage we identify key constraints. Tools that can help: brainstorming, TRIZ, simulation and flowcharts, mental maps.

Step 2 — decide how to make the most of the limitation.

To demonstrate this approach, let us take the example above of capacity constraints.

How can productivity be increased without large investments?

First, we introduced operational planning a day in advance. From the morning everyone knew what to produce and in what order. Secondly, we began to organize the importation of raw materials for the day shift in advance, as a result of which people immediately began work after the morning meeting. Third, we switched from 5/2 to 8 hours for 2/2 to 12 hours. This alone increased the number of working hours from 40 to 84, that is, more than doubled. We add a 2.5-fold increase in productivity due to loading planning (machine time increased from 30 to 70%) and we get a multiple increase in productivity. Thanks to this, the department has started to fulfill all past orders plus all major from network customers (IKEA, Leroy, Castorama).

Step 3 — Manages the system with limitation.

Now we begin to develop sales, understanding the maximum productivity of our workshop. In addition, we must develop a maintenance policy to avoid downtime and work with staff motivation.

Step 4 — extend the restriction.

We’re moving on to performance enhancement. For example, we introduce the principles of lean production, optimizing including workshop and warehouse logistics, so that there was not a large number of partially executed orders, and by the beginning of the production cycle all the raw materials were in stock. After that it is possible to plan the modernization of the equipment of the workshop to further mechanize all operations and increase productivity.

Step 5 — return to step one.

Returning to the beginning of the algorithm means finding a new constraint — the most pressing problem in the new conditions. For example, the need to modernize other producers or to plan the supply of raw materials, increase the value of the supply and the value of the goods. Thus begins a new stage of business improvement.

Where did our work on productivity lead? If at the beginning of the project we had 300—400 m2 of raw material warehouse, and the finished products were shipped from the workshop, then after all changes, we had an empty stock of raw materials, everything was started for production immediately after unloading, and the finished products were shipped from a separate warehouse with 150—200 m2. Here productivity was already limited to the supply of raw materials.

Key tools

— Method «drum — buffer — rope»

«Drum» — internal limitation, for example, limits of how much an enterprise can produce.

«Buffer» — before limitation there should be some buffer of materials stock, protecting the limit from downtime.

«Rope» — materials should be put into production only when the reserves before restriction have reached a certain minimum, not earlier, so as not to overload production (one of the principles of lean production).

— Critical chain method

Its essence is that it is necessary to reduce multitasking, get rid of the student syndrome and take into account the law of Parkinson’s.

Our brains can’t do multitasking. It’s a myth. In fact, what it does is people start switching from problem to problem, not getting any through, abandoning them, and then people have to spend their time getting into the game. This takes, on average, at least 20 minutes. Therefore, limiting the number of tasks to three, can increase human performance to 50%.

Student syndrome is the habit of many people of postponing and starting a last-minute task.

— Thought Processes

Here we use modelling and analytical schemes:

The tree of current reality is the identification of causal relationships between undesirable phenomena and the root cause of most of these phenomena.

The Conflict Resolution Diagram is the removal of contradictions and hidden conflicts in a system that often cause chronic problems.

The future reality tree is a schematic showing how the system should work with all revisions.

Transition tree — identifying and addressing possible barriers to change.

The Change Plan is an action plan with instructions for implementers.

This approach is described in artistic form in the book «Goal-2. It’s not about luck». A more formal academic language is in the book by W. Detmer «Goldratt’s Restriction Theory». You can find them by QR-code and link at the end of the chapter.

There are also eight rules in theory to follow.

— Clarity and unambiguous understanding of all terms and statements used.

— Every statement has a complete thought.

— All the causes identified cause these effects, that is, the causal link is not broken.

— The reason given is sufficient to trigger the said effect.

— Possible alternatives have been tested, and it is this reason that leads to the effect.

— Cause and effect are not confused.

— The presence of side effects in the identified cause that also point to it.

— Lack of tautology.

Constraint type

Goldratt identified the following types of restrictions:

— Physical Limitations

Limitations due to equipment performance, lack of materials, space, people.

— Political Restrictions

These and informal restrictions in the style of «we work here so» or «we have it so usual», and formal regulations and procedures. For example, the need to write letters through the first persons with approvals for 2—4 weeks of each letter instead of direct communication between the performers.

— Paradigm Constraints

These are well-established habits in work and ways of thinking, decision-making. They limit the possibilities for finding solutions and better working methods. It’s more about psychological restraints on thinking, including leaders.

Additionally, in many projects, it is the limitations in the personal effectiveness of the manager, the incompleteness of his knowledge and resources: the ability to critically approach priorities, the skills of setting objectives, concentration, attention, time, etc. eventually become a constraint on the productivity of their divisions.

— Market Restrictions

This is a situation where your capabilities and capacities are higher than market demand. This happens when you grow systematically and scale successfully and capture the entire market.

— Typical errors

Stopping the process of improvement after the next stage

You should avoid situations when after the removal of the next restriction you will say «stop, stop». Search and removal of restrictions is a continuous cycle. Restrictions will always stop. This is not a one-time project, but a permanent feature. This rule is laid down also in lean production and Kaizen philosophy (we will talk about them in the next chapter).

If you have the feeling that everything is enough, then this is the first signal of stopping development. Inertia will be fine for a while, and then degradation will begin.

— Narrow focus

Many managers focus on measurable metrics of major economic activity. And productivity is excellent, and revenue is rising, and in a good case, even profits continue to rise. As a result, they calm down, forget about building the system, work with the team and its motivation, the need to adapt to new conditions after growth. As a result, they see the problem even when all this is reflected in the figures, and begin to sound the alarm, when already half the company in chaos and extinguish the fire expensive and ineffective. You always need a system view and «helicopter vision» on work processes and product: the more areas of restrictions monitor, the better, and for this it is useful to know what are the limitations.

Chapter Summary 2

System constraint theory is an independent management tool. However, its use in digitalization projects allows you to set priorities and determine where to run and what to do first in order to obtain resources for further development. Combined with other instruments, it has a synergistic effect.

Is it necessary to use all the complex tools described above: building trees of current reality, future and so on? No. If you can look at business as a system, understand all the relationships, build a control system, it can be avoided, you will know your bottlenecks and where to direct resources as a priority. But gradually, the better your situation, the more unobvious will be the restrictions, and then you will have to dive into the work with diagrams.

At the same time, as practice shows, the main limitations are buried in the thinking of leaders. Remember the second practical example where changes were made, including changes to the operating modes of production? What do you think happened after I left and the end of crisis management? I think you’ve guessed. Managers decided that everything is fine, you can again fully include sales, without taking into account production capacity and adding «urgent orders» to the daily schedule, neglecting tactical and operational planning. In the end, three months later, everything came back: the delay started to grow, people began to complain. That is why the same Toyota warns in its thrifty production that one cannot focus on formal tools, one needs complex work, including with people. And I totally agree with that.

A detailed article with illustrations and videos is available on QR code and link below.

Chapter 3. Lean Production and 6 Sigma

Now let’s talk about lean manufacturing, a tool that allows you to build tactics and understand how to make the most of digital technology.

Lean production (lean manufacturing) is a management approach based on a constant commitment to excellence and loss management. Developed this Toyota approach more than 40 years ago, and it was one of the keys to its success and global leadership. In the 1990s, frugal production saved Porsche from bankruptcy, and now it lies at the heart of the production system of any global corporation.

In recent decades the essence of the concept was superimposed on «6 sigma» and it resulted «lean+6 sigma».

For a deeper dive, I recommend reading «Dao Toyota. 14 principles of management of the world’s leading company» Jeffrey Licker. All necessary links you will find in the article by QR-code.

Before we get to the theory, I’ll give you three practical examples of how this tool can be used in digitalization.

Example 1

Toyota will use video cameras and neural networks to analyze employee performance and identify losses, continuously optimizing work operations.

Example 2

By standardizing the report form and automating the calculations of the required coefficients, the cost of the report in one company decreased from 3000 to 300 rubles. How? By eliminating the losses for over-processing.

Example 3

Back in the first book, I was talking about a system for evaluating knowledge. With the understanding of the principles of lean production a week after the use of the system there were recommendations to optimize its work to reduce labor costs by 70—80%! And this is an annual savings of up to 500 thousand rubles, because you no longer need a separate person who is engaged in only one system. Additionally, that’s often how big corporate IT solutions work. For example, in another case it was also necessary to hire an individual to give him a job in 1C, otherwise the production manager and the master could only do that wiring. That is why it is essential in automation, digitalization (analysis of the difference between these concepts is in the first book) and business process optimization to actively use thrifty production.

Now that you understand what this is all about, let’s go deeper and look at the key tools.

4 principles

Thrift production is based on four principles.

1. Determine the cost of a specific product to the consumer

In general, Japanese people love a value-oriented approach in both projects and work. Customer satisfaction with them almost turns into a cult. This is also reflected in the P2M project management standard.

Additionally, in part, that was one of the keys to their success, despite resource constraints after the Second World War. They simply cannot be wasteful because the price of error is too high. Now, under strict sanctions, for us their path and philosophy can become a kind of cheat sheet.

This approach is more than relevant in digital projects, including domestic ones.

It is always necessary to remember who the consumer is (intermediate, finite), in what value for him. Additionally, the most important benchmark in digital projects — what losses for people can we eliminate? We will talk about what is loss through the section.

Without it, we risk introducing changes and systems that no one wants to use, and they become just expensive toys.

2. Determine the value creation flow for this product (from raw material to finished product, from order to delivery, from concept to production)

Here you need to know the whole production chain. For this there are a number of tools. In the modelling of business processes there are the designations VAD, SIPOC. Product management includes CJM (client path map) and CX (user experience). We will also talk about these tools later.

This principle allows you to understand where you have problems, where you kill the client’s desire to cooperate, where you spend resources (time and money) in vain.

Well, what is the point of introducing robotics into production if the customer has to wait a week to confirm the order and answer 100 additional questions, while the production itself takes 1—2 days?

3. Ensure continuous flow of product value creation

This is where the work begins with the processes and the elimination of all expectations, superfluous agreements.

4. Strive for excellence

Here we talk about the fact that it is impossible to once optimize everything / automate / digitize and finish. We need to come back and improve our processes and services time and time again. People, conditions, technologies, and therefore, processes need to change.

This is at the heart of, for example, Kaizen, where people on the ground themselves eliminate all unnecessary actions, improve their working conditions.

14 DAO

14 Tao Toyota — the basic «commandments» of Toyota production system and thrifty production. It’s kind of like the 10 commandments from the Bible that allow you to realize the key principles.

DAO is divided into four sections:

— Long-term perspective philosophy;

— The right process gives the right results;

— Add value to the organization by developing your employees and partners;

— Permanent solution of fundamental problems stimulates continuous learning.

Section I. Philosophy of the long term.

Principle 1. Make management decisions from a long-term perspective, even if this is detrimental to short-term financial objectives.

It’s about focusing on long-term development, not operational performance. Additionally, unfortunately, it’s the one that’s most often ignored because it’s a psychological trap.

What do owners or shareholders usually want from top management? Right, beautiful revenue figures, operating margins, EBITDA, profitability.

As a result, all development projects, as a rule, are an attempt to sit on two chairs, to develop something, to rebuild, but not to hesitate at the moment. There’s nothing wrong with that, but, alas, it rarely works. Of course, if you move systematically and progressively, then it will be, but if you have already entered a crisis or have grown up by yourself, then this approach is unlikely to work.

Here it is important to remember the main postulate of lean production: your main task, as a person, as an employee, as a company — to create value for the consumer, society and economy. In evaluating any work, one should focus on whether it solves this problem.

Section II. The right process produces the right results.

Principle 2. A continuous flow process helps to identify problems.

Its essence is to organize the work and production process with minimal losses, stocks and unfinished production. This approach, combined with well-functioning communication, allows problems to be identified at an early stage before they become a danger or crisis. In my practice, this is generally the main rule, including in the implementation of projects — collect feedback and identify problems as early as possible.

Principle 3. Use the pull system to avoid overproduction.

Are you familiar with the situation where you are being squeezed into the work of another unit? I often see the principle when different units work on their own. As a result, there is stocking of raw materials warehouses or folders with incoming service / letters / tasks.

This is the most common problem for department heads in dealing with subordinates. Many such leaders, in fact, are «transferees» — they only throw tasks over to the executive. The employee accumulates 40—50 tasks, he tries to do everything, jumps from task to task, and in the end does nothing. Additionally, as practice shows, if you limit the number of work tasks to three, productivity rises to 50%. Firstly, a person does not jump from one task to another (the process of immersing the brain in the problem takes 20—40 minutes), secondly, he has at least some diversity and variability, this protects the psyche, and allows you not to hang on to one problem.

We need to get the domestic consumer who takes your job to get what they need at the right time and in the right amount. This is the basis of the tool «Exactly in time» — new products or tasks should come only as the previous. Additionally, here Kanban boards will help a lot. About them too, a little lower.

In general, it is necessary to minimize the unfinished production (current and for offices).

Principle 4. Distribute work evenly (heizunka): work like a turtle, not a hare.

Familiar is the situation of heroism and proverbs «sometimes empty, sometimes densely»? In Japanese philosophy it is called Mura. Additionally, one of the tasks of thrifty production is to make the load evenly, without talking at the end of the month and endless heroics. And the modern planning systems, including ERP, MES and APS, that we talked about in the first book, will help. Well, so are Kanban boards if we learn to look at the process and optimize it all the time.

Principle 5. Stop production to solve problems with part of the production culture, if so required by quality.

Why were so valued, and are Toyota cars appreciated? Right, for quality. If we want to work with clients who have money, we need to ensure quality.

Quality for the consumer determines your value proposition. Additionally, that’s where the smart machine with machine vision comes in, which is to watch the product and the process and see if everything works according to the technical process. You need a visual system that immediately notifies the leader of the problem. Therefore, in my projects, I make extensive use of color tags in task cards. For example, the green label means «Everything according to the plan», blue — coordination or waiting for information, red — «There is a problem, need help». Digital tools here in general give unlimited flexibility, the main thing — the leader daily to do a review and if problems arise, to turn on and eliminate the reasons.

If we are talking about production, the tool Dzidok (equipment with machine vision or complex automation) — the foundation for «embedding» quality.

As a result, the approach by stopping or slowing down the process and getting the required quality «from the first time» will increase the productivity of processes in the future: you will simply eliminate the causes of problems and deviations.

Principle 6. Standard objectives are the basis for continuous improvement and delegation of authority to staff.

Every time I hear the thesis «we do not have standard tasks», as a rule, it means that the team simply do not know or do not want to structure the work.

Stable and reproducible working methods — the key to process management. Additionally, his task is to create a more predictable result, improve the coherence of work, and make the output more uniform. It’s the basis of flow and pull.

Yes, if you have a very young company, then for a while it will be irrelevant, you need to run the whole system, give a result, but in the end there is nothing without it. Endless creativity always leads to crisis.

Knowledge should be captured, for example, by reviewing projects, identifying and standardizing best approaches and methods. At the same time, it is necessary to encourage the improvement of these standards. In general, continuous improvement — the main creed of thrifty production. But to improve something, it must first be described and fixed. Otherwise, there will be chaos with all the consequences. Additionally, this is also more than relevant for IT. Creative guys do not like to standardize their work, but alas, it is necessary through «I do not want».

Principle 7. Use visual control so no problem goes unnoticed.

This principle is actually part of the 5th principle. As mentioned, I use color labels. But it requires discipline, and it comes from a supervisor.

Where possible, reports should be reduced to one page, even if they were critical financial decisions. There is even an «A3 Report» tool for this.

Principle 8. Use only reliable, proven technology.

Technology should help people, not replace them. If we are talking about digitization and automation, it is often better to first do the whole process manually, and then implement the digit and automate.

First, you will see the most problematic places; secondly, avoid the illusion that everything can be automated. In addition, new technologies are often unreliable and difficult to standardize, threatening the flow. The same artificial intelligence, despite all its development, still admits sometimes quite stupid mistakes.

Therefore, instead of unverified technology, it is better to use a known, well-established process. At the same time, it is necessary to encourage the study of new technologies and ways. After all, everything worked out once was new. Additionally, it is necessary to quickly implement proven technologies that have been tested and make the flow better.

Help with this can be the selection of digital technologies and solutions taking into account TRL (ISO 16290:2013). The TRL is how mature the technology we want to introduce is. Therefore, the technology has 9 levels of readiness:

TRL 1: The basic principles of technology have been studied and published;

TRL 2: The concept of technology and its application is formulated;

TRL 3: Critical functions or characteristics are validated analytically and experimentally;

TRL 4: Component or layout tested under laboratory conditions;

TRL 5: Component or layout tested in conditions close to real;

TRL 6: System/subsystem or prototype model demonstrated in near real conditions;

TRL 7: Prototype system demonstrated in operation;

TRL 8: The real system is completed and qualified during tests and demonstration;

TRL 9: The real system is confirmed by a successful operation (goal achievement).

Accordingly, the more critical the impact of new technology, including digital technology, on the final product, and the higher the reliability requirements of the product, the higher the maturity level should be.

Section III. Add value to the organization by developing your employees and partners.

Principle 9. Educate leaders who know their business thoroughly, profess the company philosophy and can teach others this.

It is better to educate your leaders than to buy them outside the company. First, it is one of the key rules of motivation. When you constantly hire outsiders, you discourage your people. They begin to lose faith in the future. As a result, they focus on their goals and do not have to expect their full contribution. Second, leaders who know their business by default have high expert power and know all the pitfalls of your activities. Additionally, digitalization and automation are all about that.

Train staff in the basics of lean manufacturing, design management, digitalization, and collect feedback from the beginning.

In addition, a leader should not only perform his tasks and have the skills of communicating with people, he should also profess the philosophy of the company and set a personal example of attitude to the case.

Principle 10. Educate exceptional people and form teams that profess the company philosophy.

Principle 11. Respect your partners and suppliers, make them difficult and help them improve.

You can be as digital as you want, but if your partners live in paper, the effect will be limited. Here, as in systems constraint theory, chain strength is determined by the weakest link.

It is necessary to create conditions for partners to grow and help them to demonstrate their high efficiency.

Section IV. Permanent solution of fundamental problems stimulates continuous learning.

Principle 12. To understand the situation, you need to see everything with your own eyes (genti genbutsu).

How often have I seen stories where TOPs trusted their managers and reports on the computer? Here is a practical example. The founder of the company was from the production. Weekly he went to the production. And in the end, people understood that their work was important, motivated, and he had reliable information.

But his successor had a classical management education. He formed a team of managers, a system of reports. But what do employees want? To keep them safe and stable. That’s normal. However, with each step, from each leader the information becomes more distorted, and as a result, a distorted view of the situation is formed at the very top, which means that decisions are made based on the erroneous opinion. This is, for example, one of the main problems of public administration.

If this rule is combined with high-quality, automated data collection, transparent analytics, this problem can be avoided.

As a result, solving problems and improving processes, you need to see what is happening and personally check the data, rather than theorize, listening to other people or looking at the computer monitor. Thinking and reasoning must be based on data that are verified and sure. Even company executives and business executives must see the problem for themselves, only then will the understanding of the situation be genuine, not superficial.

Principle 13. Take your decision slowly, on the basis of consensus, weighing all possible options; when implementing it, do not delay (nemavasi).

It can also be called «think slowly, decide quickly». One of the basics of management is the need to evaluate alternatives. Making decisions based on one opinion is too dangerous and risky. If this is sometimes the only development option for young companies, the further, the more often it is necessary to use consensus, and this requires the development of the issue and several people with different opinions and psychotypes. On this, among other things, the concept of Adizes is based — one person cannot combine all the necessary competencies, you need a versatile team. To that end, it was necessary to learn to discuss views openly and to overcome conflicts.

As a result, one cannot make a clear decision on the way forward without weighing all the alternatives. In this case, there are less risks and the desire to go back and redo. And when a decision has already been made, you need to act. For example, when Toyota was developing her Prius, she worked very hard on possible variations of the hybrid approach. However, by assessing possible alternatives, they focused on one option and promoted it only, it became the de facto standard worldwide.

Nemavashi is a process of joint discussion of problems and potential solutions in which everyone participates. His job is to gather all the ideas and develop a consensus on where to go next. While such a process is time-consuming, it helps to broaden the search for solutions and to prepare the ground for rapid implementation.

Principle 14. Become a learning entity through tireless introspection (Hansei) and continuous improvement (Kaizen).

Do you think it’s possible to optimize everything? Right, in the beginning, we said that goals, objectives, technologies, products can change, and that means we need to constantly improve.

What are the approaches? You can hire consulting agencies, you can initiate regular modernization and restructuring. But with this approach, people will pretty quickly become disappointed in all this, and a culture of inert to any changes will begin to form: people will have in mind the idea that it will pass.

The Japanese prefer to follow the path of constant development in small steps, initiating changes from the performers. Additionally, for example, in digitalization — you can initiate a giant program of digital transformation, invest huge resources, and the output does not get effect.

It is better to start with the small stages of digitalization, and then, when the competencies and the conscious understanding of the need for global digitalization are formed, begin to implement global systems.

In the first book, I already gave examples of both cases: a failed implementation experience at once A total and expensive asset management system and a successful experience of using free Google tools to organize production. It’s not necessarily the right path, but I’m a proponent of that evolution.

To realize this principle, it is necessary to:

— once the process has stabilized, use tools for continuous improvement;

— create such a process that almost does not require reserves. This will immediately identify the loss of time and resources and do not start the «disease». When losses are obvious to all, they can be eliminated through continuous improvement (Kaizen);

— collect and preserve company knowledge, prevent staff turnover (i.e., understand the nature of motivation), monitor the progressive promotion of employees and preserve the accumulated experience;

— at the completion of projects, including implementation, carry out gap analysis (hansey) and openly talk about them. Following the analysis — implement changes in business processes;

— standardize the best techniques and techniques instead of inventing a wheel every time a manager changes, that is, describing business processes.

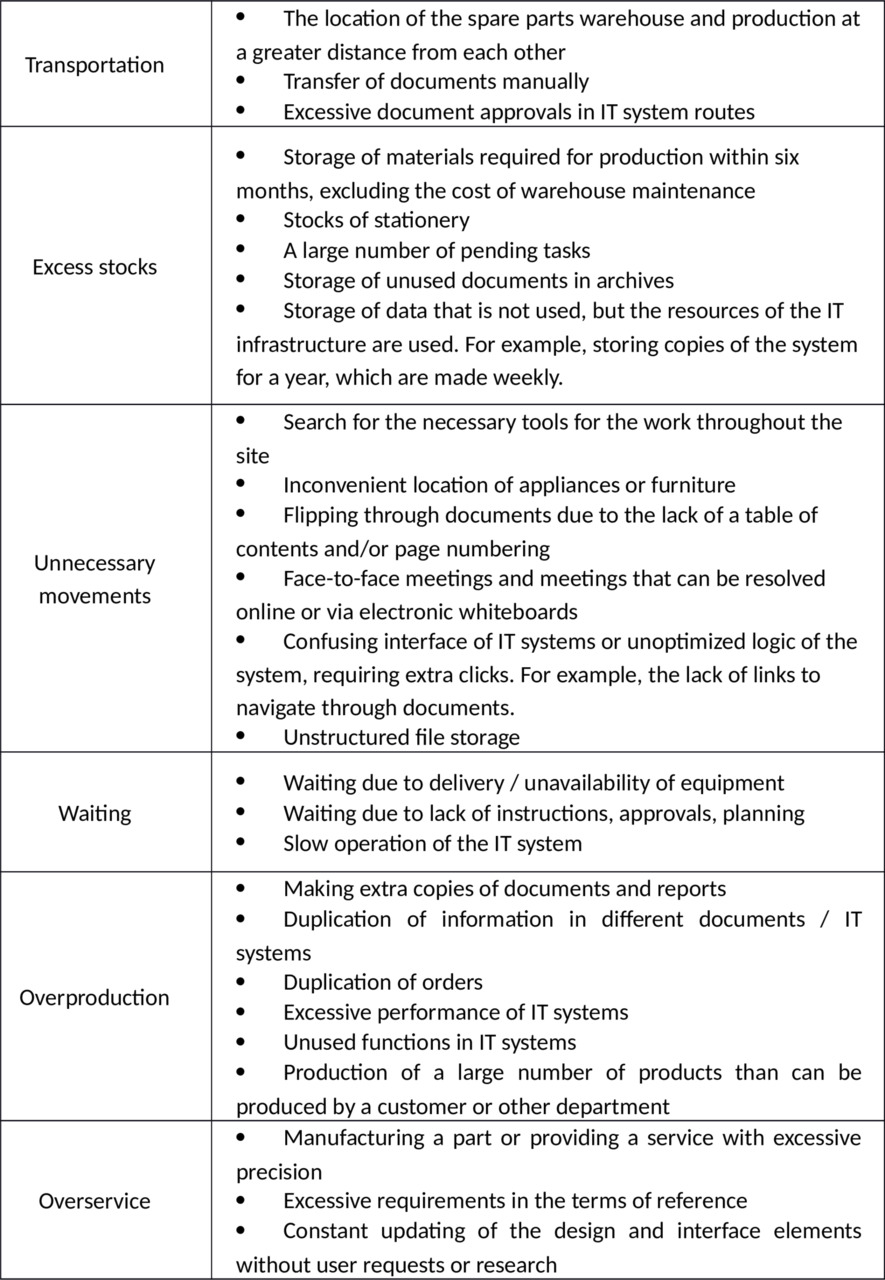

Muda, Mura, Muri and Loss Types

Mud, moody, moody are strange words, aren’t they? The essence is simple.

Let’s look at these basic concepts.

Muda is two kinds of loss:

1. Actions that do not create value but are unavoidable. For example, transportation, paperwork — it is impossible to remove them from the process, but it is necessary to strive to reduce, say, automation of preparation of mandatory reporting. In my experience, with the help of ordinary Exel, I was able to reduce the labor cost of a mandatory and unnecessary report from 8 hours per month to 30 minutes.

2. Actions that do not create value at all and should be excluded from the process completely. For example, waiting, stocks, marriage, etc.

Mura is uneven. If demand is uneven, queues are formed, execution time increases. Additional materials and supplies are required to meet peak demand. Working in emergency mode tires people and reduces their efficiency and quality of work.

All this also generates losses — marriage, waiting, excess supplies, the need to redo.

Moody is an overload of people or equipment.

We make machines or people work to the limit. Overloading people threatens their safety and causes quality problems. Overloading equipment leads to accidents and defects, which in the end also leads to losses.

These three «M» represent a single system.

Often the root of the problems — «Mura», as unevenness leads to overload «Muri», which in turn causes many other losses («Muda»).

Let me remind you that the goal of digitalization, automation and transformation is to reduce losses, mainly in working with information. Additionally, before we initiate any project, we need to understand what losses we want to eliminate.

1. Overproduction

The most common problem, which is the cause of most others. Remember the example in systems restriction theory where the sales department sold more than it could produce? Or when we make five copies of documents, when you only need one? All this is overproduction. This leads to overburdening of units, and high stocks of unfinished production or finished products in warehouses, which also increases the number of rejects.

Reasons — large batches production and unexplored demand, long retraining / restructuring.

Planning systems and deep market intelligence through big data collection can help.

2. Waiting

This is all the time during which people or equipment expect resources, technological operation, data, unnecessary coordination. The e-workflow projects are also designed to address these losses. It is only in such projects often forget to do rewrite processes, and then the electronic workflow begins to complicate the life of employees.